The door frame roll forming machine is used to produce the door frame in large quality, which used in to steel door structure. There are 3 types of this door frame machine in designing:

1Door frame machine with chain transmission

2Door frame machine with gear box transmission

3Door frame machine with reducer transmission.

Also the door frame machine can be designed with different cutting systems: There are two cutting systems below:

1 Power fly saw cutting system

2 Hydraulic cutting system

Here we take the gear box transmission and hydraulic cutting system door frame roll forming machine for an example, below is the machine details of this type machine. The seasons why we take this door frame machine as an example is because this machine is popular in designing, and with reasonable price that most customers can accept its price.

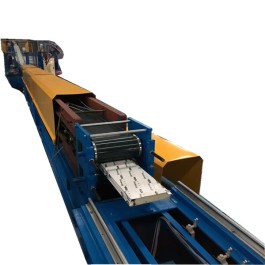

1 .Below is the picture of this door frame machine with hydraulic cutting and gear box transmission

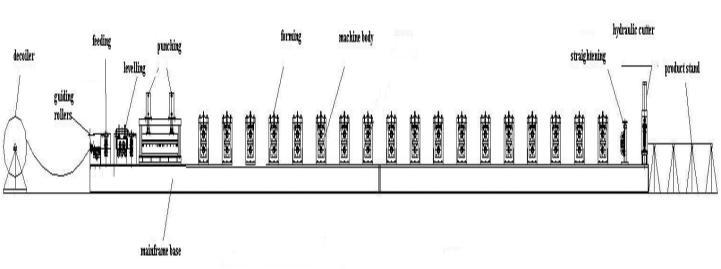

2 .Door frame machine Processing flow diagram of machine

Manual de coiler→Guide roller→Feeding material →Leveling→punching→roll forming→strengthening→Hydraulic cutting→product receiving table

3.Door frame machine technical parameters

| Configurations | Manual de coiler, Guide roller, Feeding material, Leveling, punching, roll forming main body, strengthening ,hydraulic station, Delta PLC control system, run out table | |

| Manual De coiler | Inner Diameter | 450-508mm |

| Outer Diameter | max 1500mm | |

| Max Coil width | 400mm | |

| Capacity | 1.5T | |

| Punching System | Punching the holes at end and middle The mold design as the profile drawings |

|

| Leveling Part | Put the raw material through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate iron panel. | |

| Roll forming system | Feature | Ensure the stability, accuracy and long life |

| Main forming machine Size | 3500mm*900mm*1000m(L*W*H) | |

| Main forming machine weight | 3.0 Ton | |

| Voltage | 380V 50Hz (380 V is China normal voltage, but the voltage can be customize by customer.) | |

| Method for fixing roller | Memorial arch frame | |

| Material of shafts | 45# steel Thermal refining | |

| Transmission method | gear box | |

| The main shaft material | No. 45 steel quenching and tempering treatment | |

| outer shaft diameter | 70mm | |

| Wheel material | quenching process of GCr15 bearing steel HRC58-60 | |

| Roller | 18 stations | |

| The main motor power | 5.5kw | |

| Hydraulic System | Hydraulic oil | 46# |

| Hydraulic power | 4kw | |

| Components | The system includes a set of hydraulic tank , a set of hydraulic oil pump, two hydraulic pipes. and two sets of electromagnetism valves | |

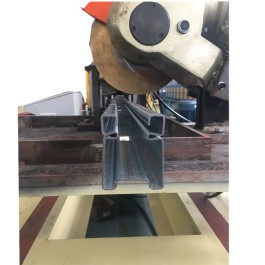

| Shearing Mechanism | Feature | Ensure stability, precision and cutting speed |

| Function | Automatic cutting controlled by PLC. It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products. | |

| Material of blades | Gcr12 quenched | |

| Power supply | hydraulic power | |

| Frame | Pillar style with rack & pinion system | |

| Stroke switch | non-contact photoelectric switch | |

| Control Device | Control | By PLC |

| PLC language | As required | |

| Touch screen | Delta | |

| Function | Automatic length and quantity measurement | |

| Include | Equipped with movable switch , air break, radiator, transformer & electric leakage protector for operation convenience and safety. | |

| Feature | Adopted PLC , transducer, touch panel from Mitsubishi Japan to ensure high speed with stability, precision and lifetime. | |

| Other part | Runout table | 60*40mm welded, length could adjustable. |

| Easy damaged parts | conk 2 pcs, fuse-link 4 pcs | |

| Rubber mat | 1 pcs; | |

| Bolt spanner | 1 pcs | |

| Counter | A counter measure length, pulse and the length is determined. OMRON encoder to measure the length. |

|

| The run out table | 2 sets | It adopts welded steel and supported roller to transmit the products. |

4. This door frame machine can be customized made according to your demand, It can be designed with hydraulic cutting, the flow saw cutting, the transmission drive, the gear box drive, the reducer dear box transmission and so on. Also, the machine color , the machine un coiler system, the machine electric system and so on, So it you need this door frame machine, please feel free contact us, and tell us your requirements, we are sure to customize the door frame machine for you with high quality and reasonable price!

If you want to know more information about the shutter door roll forming machine, please refere to this article. And for this machine, if you have any problem, please contact us at any time.

Next: Hydraulic decoiler with loading car or without for roll forming machine