Supermarkt shelf panel roll forming machine is a kind of roll forming machine for making shelf panel fully automatic.

The machine is composed by the following elements:coiler,guide frame,lever/feeding section,continuous bottom hole punching section,forming section,positioning and cutting section,collection table and electrical control system etc.

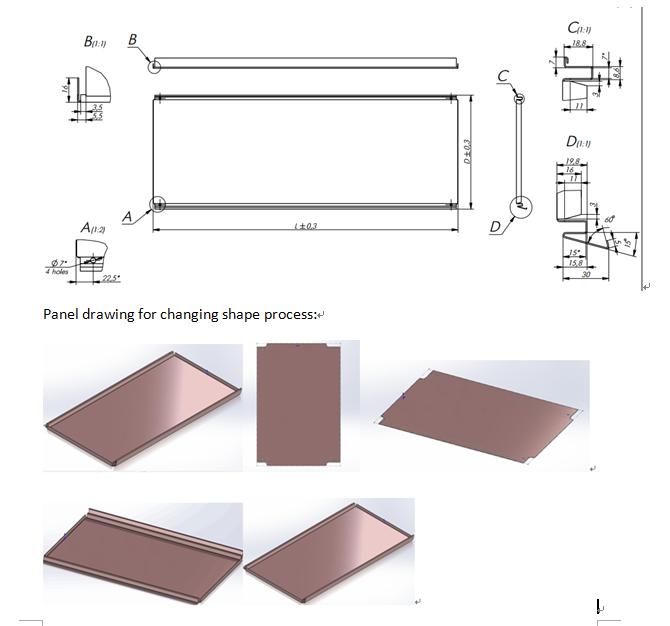

For the adjustable size shelf panle picture and drawing profile for your refernce:

Why choose ZT Supermarkt shelf panel roll forming machine?

1.Professionally design according to the drawing profile.

2.Size adjjustable fully automatic.

3.Panel width could be adjusted eassily.

4.Pillar stands design to make sure machine working speed and long time to use

5.Transmission by gear, working steadier.

6.All the electrical elements are best brand, like PLC Panasonic, the motors are Semens.

Main parameters of shelf panel roll forming machine:

| NO. | Item | Introduction |

| 1 | Item Model | ZT-SP-02 |

| 2 | Working speed | 8-10m/min(not include shearing) |

| 3 | Supported material thickness | 0.5-0.8mm |

| 4 | Control method | Panasonic PLC |

| 5 | Decoiler | Manual version 3 ton |

| 6 | Roller station | 26 stations of rollers |

| 7 | Punching for fore angel | For left and right, two sets |

| 8 | Bending for post shearing | One set |

| 9 | Roller material | 45# steel after quenching processing HRC58-62 C, chrome plated surface |

| 10 | Shaft material | 45# steel processing,shaft diameter=¢ |

| 11 | Main power | 5,5kw |

| 12 | Hydraulic station power | 11kw |

| 13 | Hydraulic power | 40Mpa |

| 14 | Shearing blade material | Cr12Mov, 58-62 HRC |

| 15 | Length tolerance | 3m±1.0mm |

| 16 | Electricity | 380V, 50HZ,3 phrase or customize |

| 17 | Transmission method | 1 .0 chain |

| 18 | Machine frame | Pillar type |

| 19 | Machine color | Blue or customize |

| 20 | Machine size | 11.5*1.5*1..4 meter |

| 21 | Delivery date | 58 days |

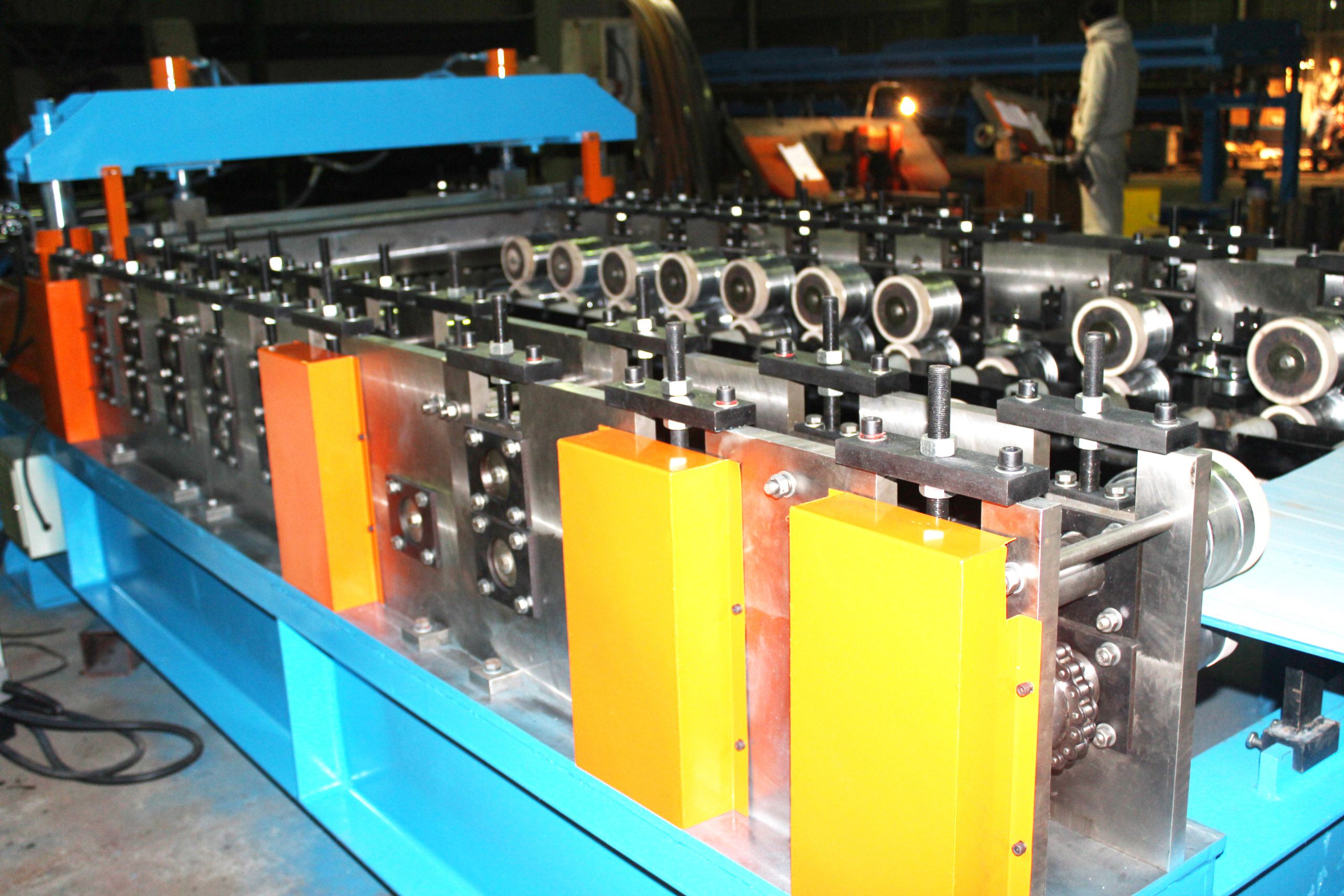

Here is the shelf panel roll forming machine pictures:

Simply machine working video for you refernce:

For this machine, if you want to know more know more information, please contact us at any time.

Next: Shelf beam making machine/interlocked square pipe making machine