In the market, there are many types slider rail of rolling shutter door, like molding type of aluminum, or simple U channel or others. But here I share one type of rolling forming type, something line U channel but a little complicated. Compared with U channel, this type is safer to use. But for the macine, it takes same working principle of cold rolling forming. The machine working speed is around 25m/min.

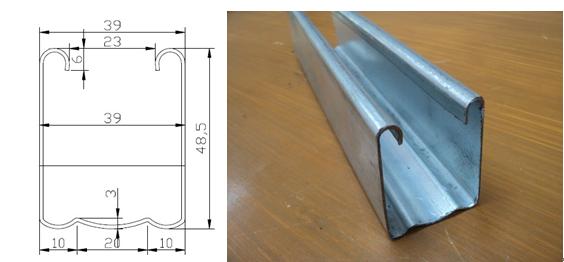

Here is the Shutter door slide rail drawing profile for your reference:

From the following pictures, let us check where the Shutter door slide rails are used:

Here are more parameters of Shutter door slide rail drawing profile for your reference:

1).Main axle material quality: 45# steel quenching and retempering treatment, outer diameter Phi 60mm.

2).Roller material: 45# steel quenching processing HRC58-60°

3).Number of forming steps:10steps

4). Main electrical machinery power: 7.5KW

5). rolling speed: 10meter/minute

6).Transport: by gear

7). Main engine outlook size: Approximately long 4.5M× width 1.3M× high1.4M

8).Voltage: 380v 50Hz 3phase

The machine working process:

decoiler→feeding→ forming→straight system→products

For other element of the Shutter door slide rail rolling forming machine:

| Decoiler | Manual decoiler |

| Hydraulic decoiler | |

| Motor | Chinese brand |

| World famous brand like Simens | |

| Shearing system | Hydraulic shearing |

| Flying shearing | |

| Stacker | Normall manual runout table |

| Fully autoamtic stacker | |

| Note: for this machine, all elements could be customized. If you need, please tell me in advance. | |

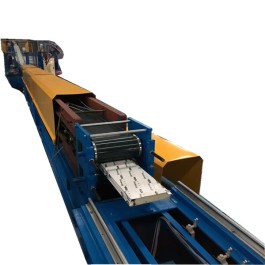

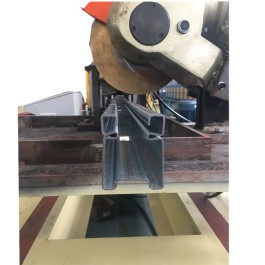

Here are some machine pictures for your reference:

For this machine, if you need to know more information, please contact us at any time.