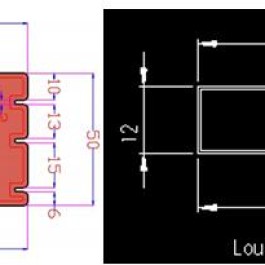

Round pipe interlocked seam roll forming machine could you be used to make interlocked seam round pipe in batch and fully automatically. Interlocked seam is a kind of seaming methold. By pressing and roll forming mahcine the two edges together and then make the narrow strip to pipe shape. Here are two pictures of interloacked pipe for your refernce:

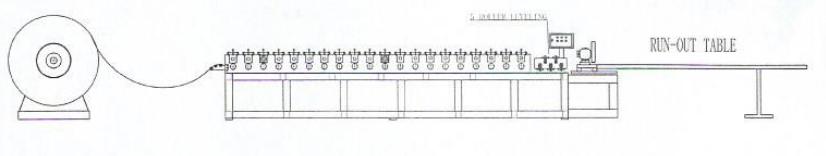

Round pipe interlocked seam roll forming machine working process:

Decoiler—Feeding—Leveling—Roll Forming--Cutting--Product Table

Main elements of Round pipe interlocked seam roll forming machine:

| NO. | Item | Parameter |

| 1 | Decoiler | ID:450-500mm OD:1200MM Max loading:3 Ton Max width:300mm |

| 2 | Main Roll Forming Machine and size system | 1.Roller station:20stations 2.Shaft material:45# steel Outer diameter:50mm 3.Roller material: GCr15 quenching at 58 to 60 degree 4.Transport: Chain 5.Forming Speed: 0-8m/min 6.Motor:5.5kw 7.Machine :8.5mx0.8mx1.45m 8.Voltage:380v,50Hz,3 phase (Customized) |

| 3 | Flying cutting saw | 1.The material of blade: Cr12Mov-hardening HRC 58-62℃ 2.Length Tolerance:3m±1.5mm 3. Flying cutting saw, can make sure the perfect shape after shearing. |

| 4 | PLC Control | 1.Screen: touch screen 2.PLC: Delta 3.Automatic-length measurement 4.Automatic-quantity measurement |

| 5 | Hydraulic System | 1).Advanced hydraulic system from Taiwan 2). Power:3kw |

| 6 | Output frame | Could be welded locally according to customer needs. |

Main machine pictures:

How to order Round pipe interlocked seam roll forming machine?

Differnet with other roll forming machine, for making pipe machine, we do not need drawing but those information is very important:

1.What is the mateial and material thickness

2.Pipe diameter range.

3.For the pipe making machine, one machine can make many sizes pipe within one range. But for different sizes, you need to change moulds.

If you want to know more information about this machine, please let me know and contact me at any time.

Next: Random combined light keel machine