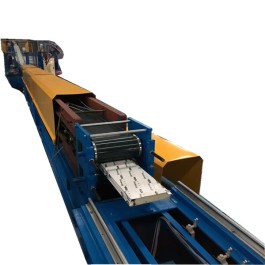

PU foamed roller shutter door roll forming machine could be used to make various sizes and types rolling shutter door by roll forming principle. The working flow of roller shutter door roll forming machine is: Decoiler—feeding device—main forming—PU injection ---straighten device—Cutting ---run out table.

The rolling shutter door is composed by the following elements: decoiler, Guide Feeding device, main forming machine, Foaming machine, Straighten device, flying saw cutting machine, finished products table, PLC control system and Spare Parts and Tools.

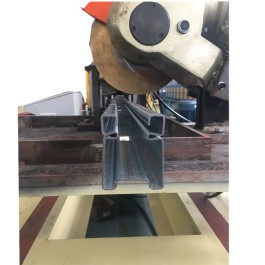

Take the following drawing profile of rolling shutter door for example:

Here is some basic information of roll forming machine for your reference:

Forming stands: about 46 stands

Roller material GCr15: model steel, HRC50-54

axial diameter: Φ40mm

Main axial material: No 45 steel HRB260-280

Driving part is chain transmission

Frequency conversion decelerating:Delta

PLC control: fix length control ±1mm (Delta)

Main components: CHINT, DELIXI

The precision of roller: less than ±0.5mm

Main roll forming machine motor: 380V, 50HZ, 11kw (or according to your requirements)

Machine basement material: H beam

1.Pneumatic flying punching machine: 1 set

Material of cut: Cr12Mov

Quench: HRC58-62

2.Finished products table: 1 set

Working speed: 8-15m/min

3.dimensions of main forming machine

24000mm×600mm ×900mm

Machine weight: about 7.5T

For this PU foamed roller shutter door roll forming machine, if you want to know more, please contact us at any time.

Next: Our second order from Sir Lanka