Zhongtuo metal stud and track roll forming machine offer builders a competitive alternative to traditional wood trusses.This machine provides significant improvements over other light gauge steel trusses currently available. Flexibility and design advantages allow architects, engineers, contractors and owners' exceptional versatility and performance characteristics not available with any other type of truss material.Our machine could update with the fashion for providing new design increases material efficiency, ease of fabrication, simplicity of erection, and improved safety of material handling. No matter for running business or for big construction, this machine will be good helper for you.

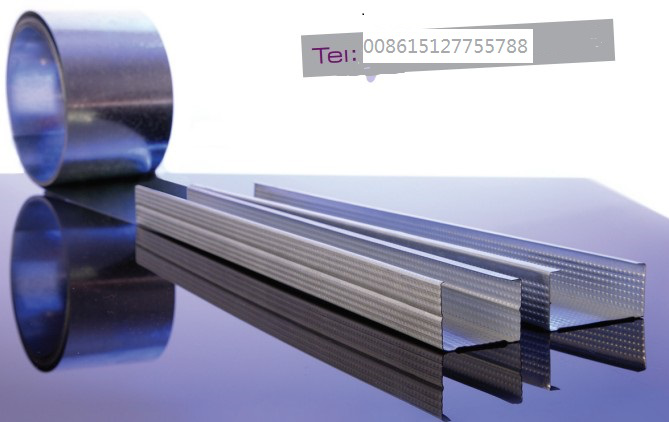

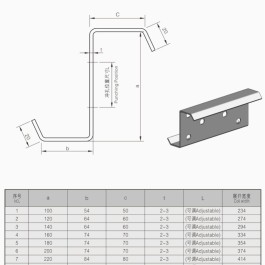

Take the following drawing profiles for examples to show how the Metal stud and track is made by the rolling forming machine.

Recent investment Zhongtuo stud and track roll forming machinery has allowed us to produce the complete range of non load bearing 'C' stud and associated track sections without the need for conventional changeover time. This covers 44mm, 48mm, 50mm, 60mm, 70mm, 73mm, 92mm and 146mm 'C' studs and 46mm, 50mm, 52mm, 62mm, 72mm, 75mm, 94mm and 148mm track sections in regular, deep and extra deep leg lengths. Here are more popular drawing profiles picture for your reference:

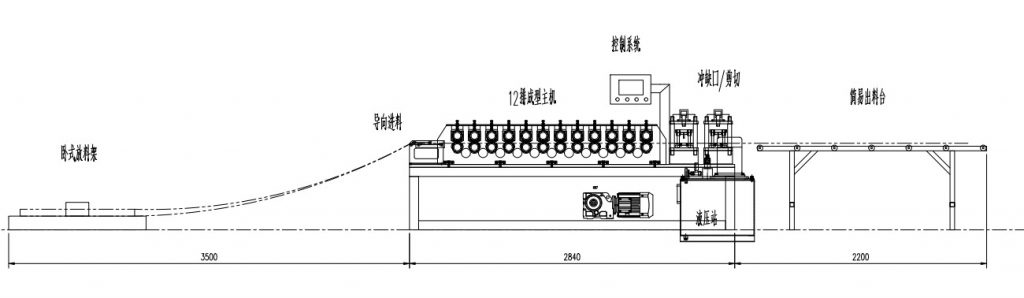

Machine components of Zhongtuo stud and track rolling forming machine:

De-coiler------------------------------------------1set

Forming machine--------------------------------1set

Cutting device -----------------------------------1set

Punching device----------------------------------1set

PLC control box --------------------------------1set

Hydraulic pump station-------------------------1set

Production support table-----------------------1set

Metal stud and track rolling forming machine working flow:

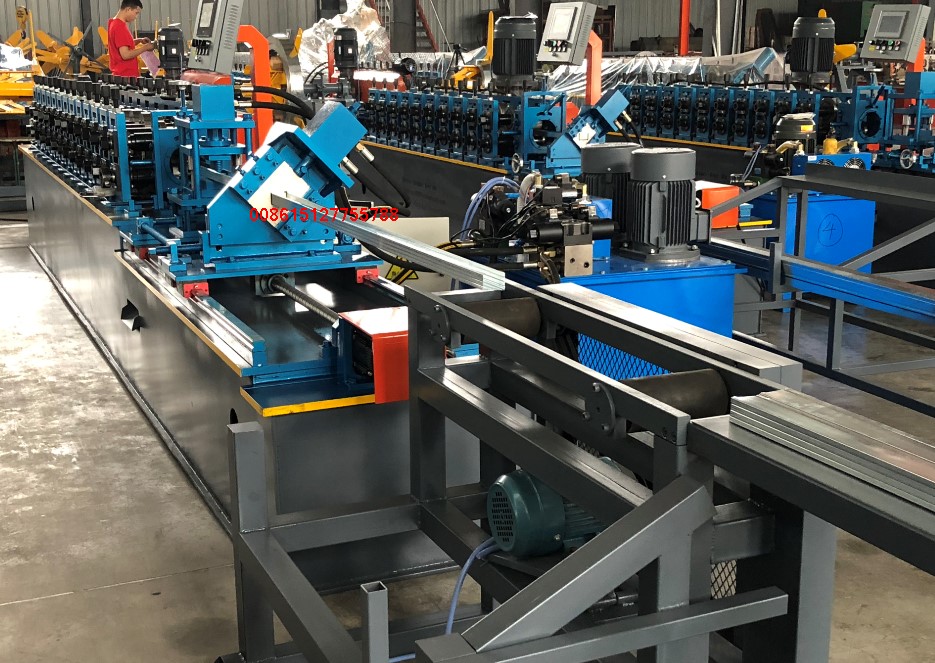

Metal stud and track rolling forming machine pictures for your reference:

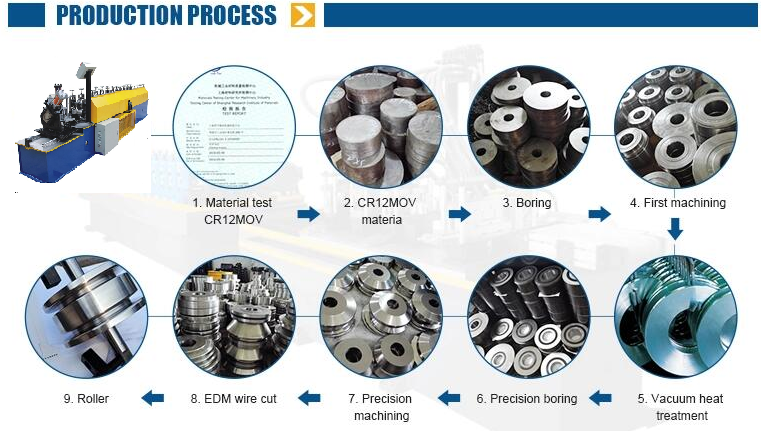

Why choose Zhongtuo metal stud and track roll forming machine?

- We choose the best mateiral GCR12mov as the roller material.

- We do the accurately processing for making sure the stud and track accuracy.

- We Do the strickly testing after roller have been made.

- For the machine frame and design,we do the fasion design to make sure it is safe for workers and morden for using.

- For the stud and track rolling forming machine, we can reach speed of 80 meter per minute or at least 25 meter per minutes.

- If you need our Zhongtuo stud and track roll forming machinecan help you punch the logos on them.

As to the usage of the Zhongtuo stud and track roll forming machine:

Other products to compliment the range of drywall steel sections are resilient bar, supplied as standard 3,000mm lengths, wall liner supplied in lengths of 2,400mm, 2,700mm, 3,000mm and 3,600mm and wall liner tracks supplied as 3,000mm lengths.