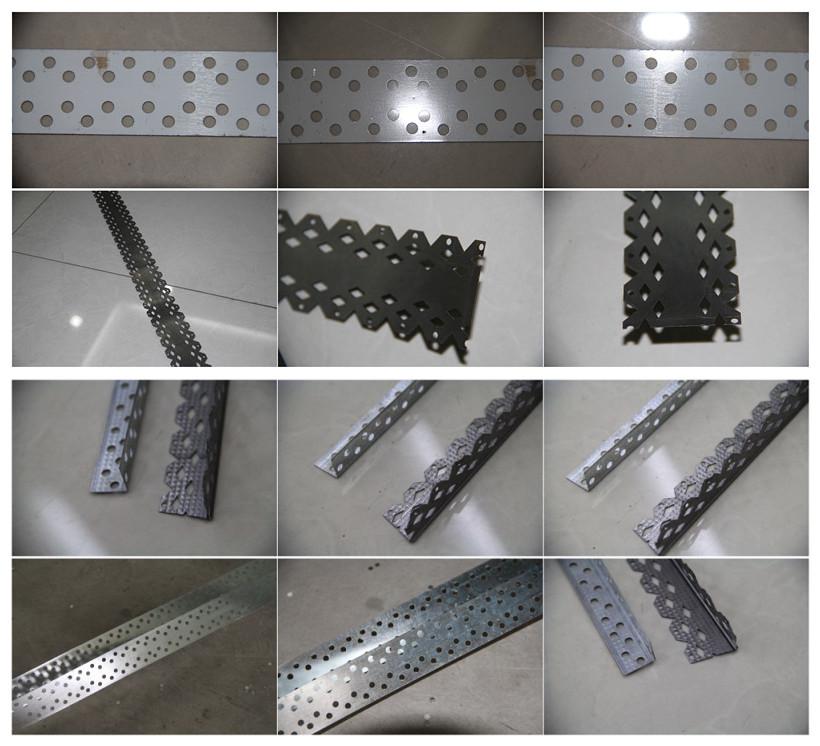

Different with traditional wall angles, now the meshy type wall angle is quite popular. The meshy type wall angel either could be used with ceiling or drywall building to make the ceiling or drywall stronger. Base on this need, we developed new type meshy type wall angle roll forming machine. Here are some pictures of meshy type wall angle for your reference:

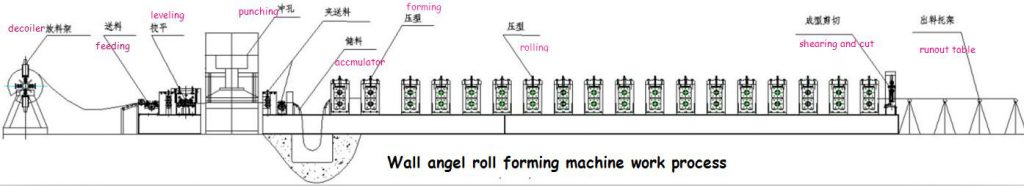

Work process of Meshy Type Wall Angle Roll forming machine

decoiling(decoiler) coiler feeder(for sending coil to the punching machine)punching punching(punching mesh size by punching) feeding roll forming machine shearing and cutting runout table.

The meshy type wall angle roll forming machine is composed by the following elements:

| No | Item Name | Quantity |

| 1 | Decoiler Option A: Hydraulic Decoiler Option B: Motor Decoiler Option C: Manual Decoiler |

1 Set |

| 2 | Coiler feeder | 1 Set |

| 3 | Leveling part | 1 Set |

| 4 | Punching part | 1 Set |

| 5 | Roll forming part | 1 Set |

| 6 | Shearing and cutting part | 1 Set |

| 7 | Hydraulic Station | 1 Set |

| 8 | PLC control system | 1 Set |

| 9 | Runout table | 1 Set |

Machine meshy wall angle roll forming machine:

Main part introduction:

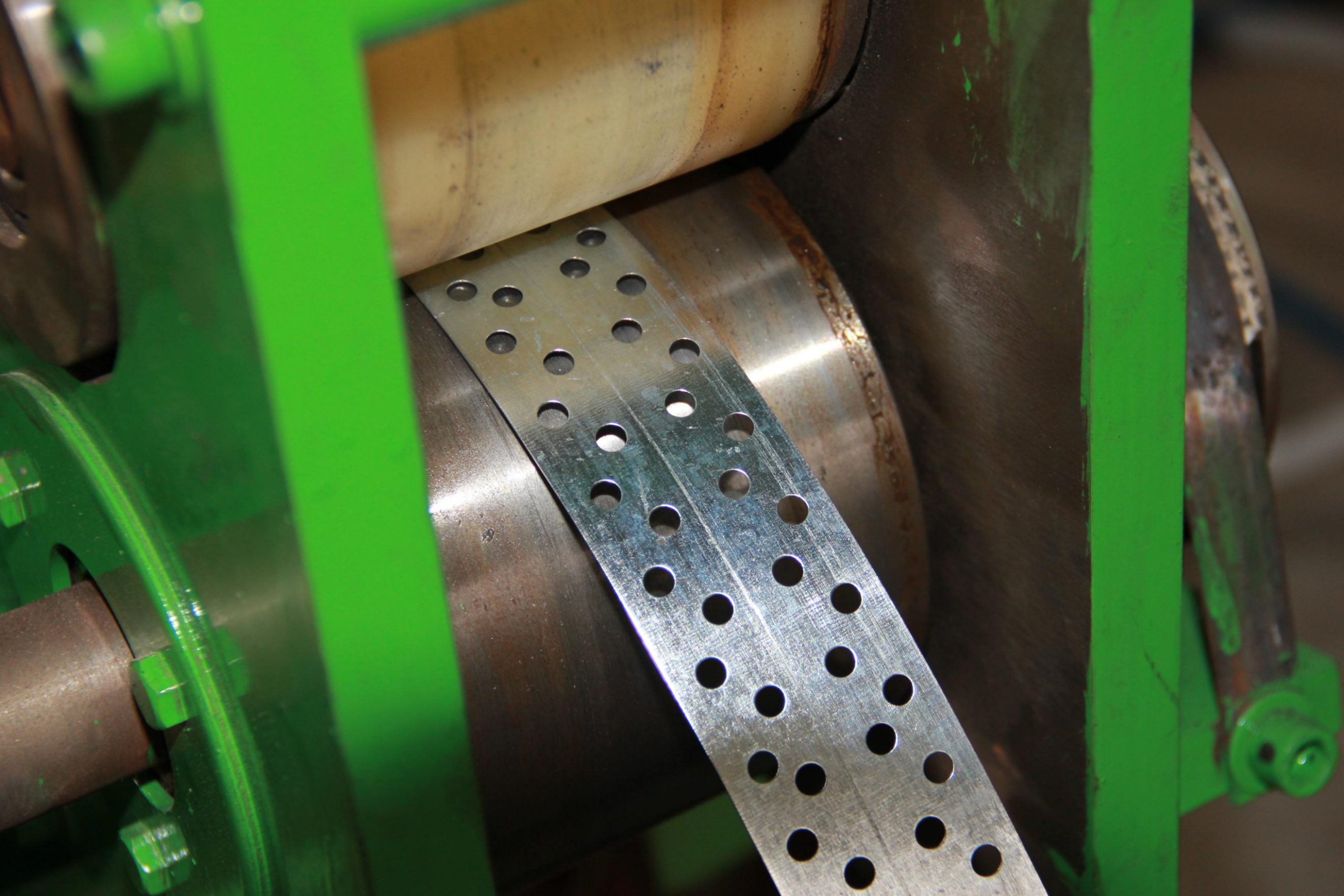

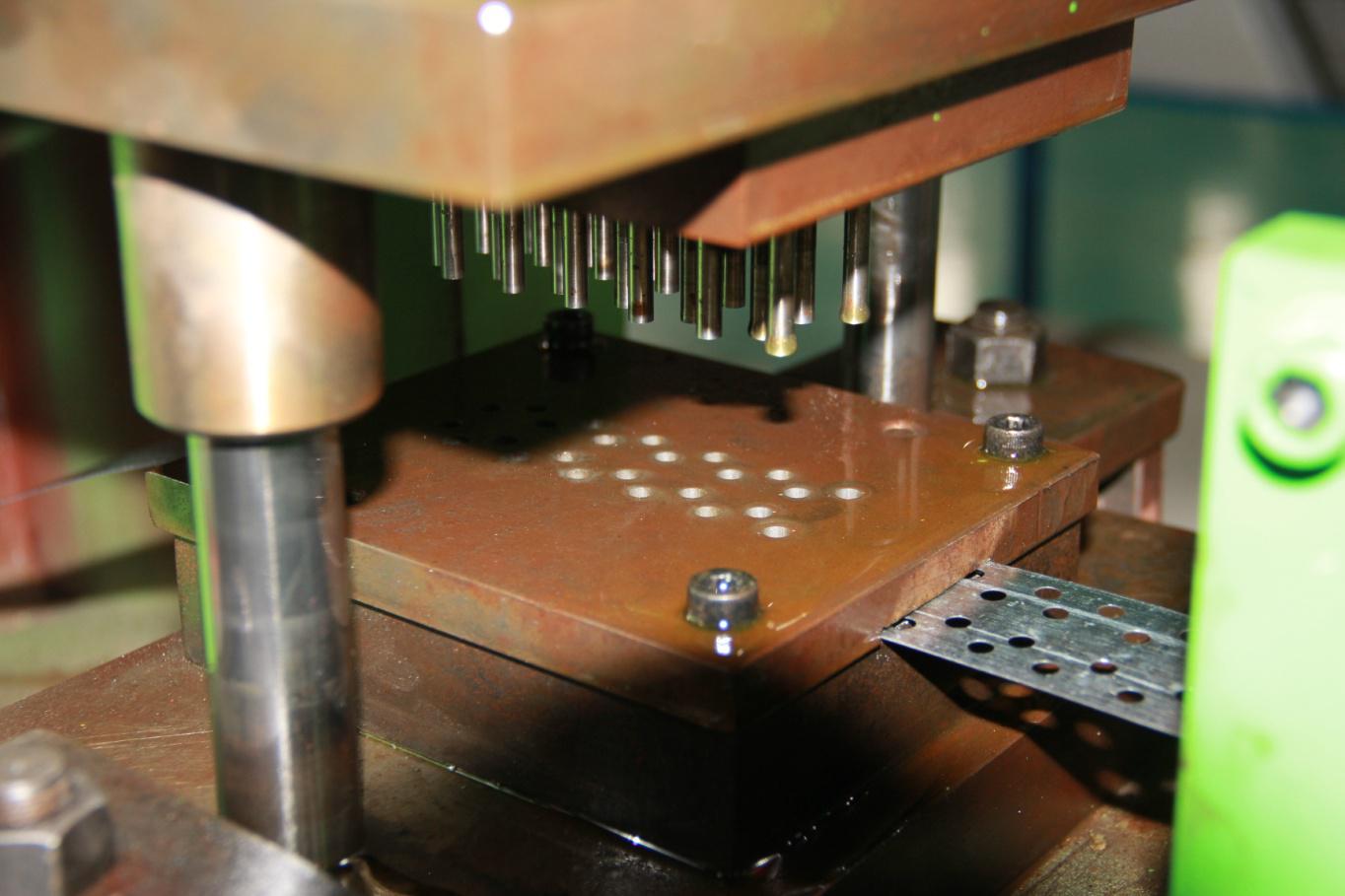

Punching part

This part will be punching coil to meshy type and for further roll forming.

Here is the main roll forming machine pictures for your reference:

Feature of the shearing part: Ensure stability, precision and cutting speed

Function: Automatic cutting controlled by PLC

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

Material of blades: Gcr12MoV quenched

Power supply: hydraulic power

Frame: Pillar style with rack & pinion system

Stroke switch: non-contact photoelectric switch

Components: It contains one set of cutting tools, one

hydraulic tank and one cutter machine.

If you want to know more details of this machine, please contact us at any time. Meanwhile for wall angle, if you need the type used together with T grid without hole wall angle machine, please refer to another website page.