Medium duty warehouse rack rolling forming machine is design to make the shelf rack in batch fully automatically. Combined structure, without any bolts, beautiful appearance, scientific structure, convenient installation and disassembly; layer height can be adjusted freely with a pitch of 50mm, each layer can carry up to 400kg under uniform distribution; the surface is treated by electrostatic spray, anti-corrosion Rust, sturdy and durable; widely used in supermarkets, enterprise warehouses and institutions; this product has reached the level of similar products in developed countries.Based on the market needs, we designed the machine to make the rack first as to the other elements, we will introduce one by one.

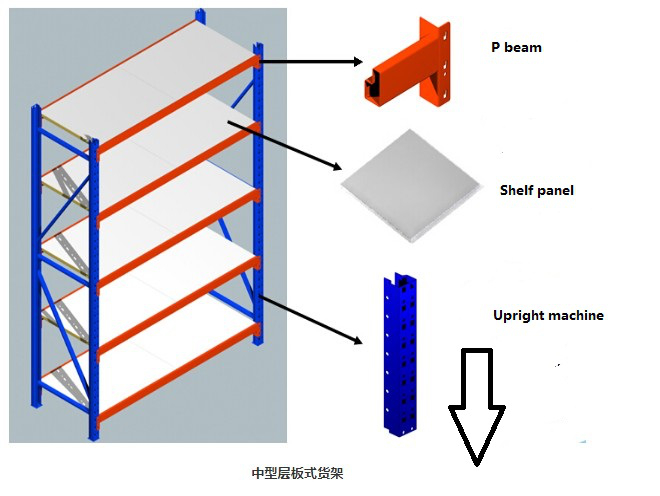

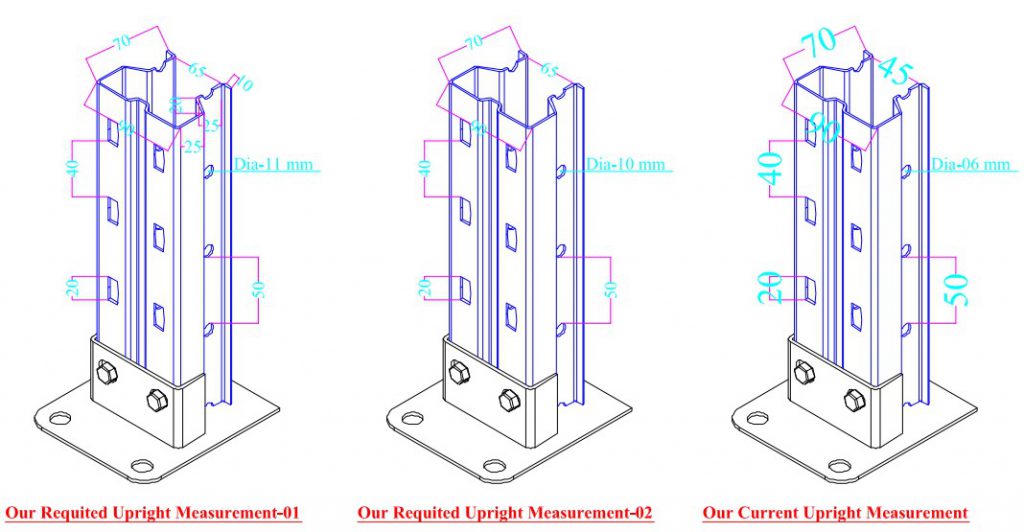

Here is one warehouse rack drawing profile for your reference:

The Medium A type shelf rack making machine is composed by the following elements:

| 1 | 3 Ton Manual decoiler | 1 set |

| 2 | Yang Li brand Punching system 80 Ton | 1 set |

| 3. | Coil feeder | 1 set |

| 4 | Leveling Machine | 1 set |

| 5 | Roll Forming for the shearing, please make good and update and change the cutting metod for good shape no any bending.

The entire PLC brand Dleta. The Electrical component Schneider |

1 set |

| 6 | Hydraulic Cutting | 1 set |

| 7 | PLC Control System | 1 set |

| 8 | Hydraulic Station | 1 set |

| 9 | Run-out Table-(Un-powered) | set |

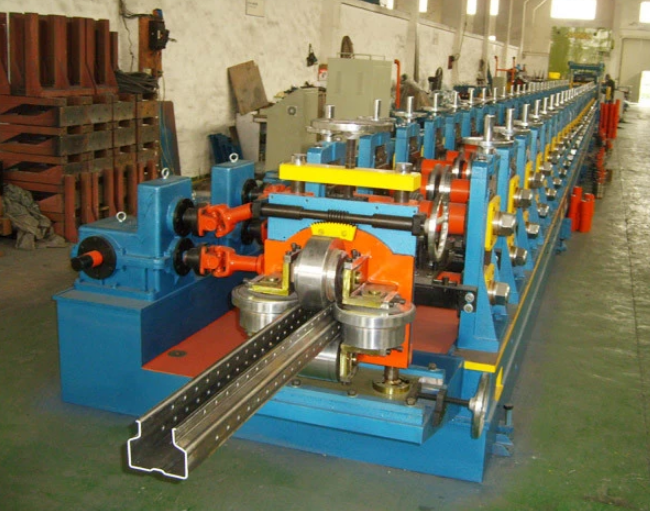

And the Medium A type shelf rack making machine we designed like this:

More details of the shelf rack making machine:

- Suitable Plate Material: thickness 1.5-2.0mm, Galvanized steel or blank steel

Working Speed: 12-15 meters / min

3. Forming Steps: 19 stations, drive by gear boxes

4. Material of Roller: Gcr15, Quench HRC58-62 Plated Chrome

5. Material of Shaft: 45# Advanced Steel (Diameter: 76mm), thermal refining

6. Driven system: Chain Driven 1.5 inches 20A double chain with longer shafts

7. Main Power with reducer: 22KW WH Chinese Famous

8. Cutting: Hydraulic Cutting Cr12mov

9. Material of Cutting Knife: Cr12Mov, Quench HRC58-62

10. Hydraulic Station Power: 4KW Wuxi Wanshen Famous Chinese Brand

11. The whole machine is controlled by industry computer-PLC.

12 PLC--Panasonic, Japan English and Chinese Language

13 Touch Screen--Panasonic Japan

14 Encoder--Omron, Japan

And for the machine, if you need to know more information, please contact us at any time.

Next: Zhongtuo rolling shutter door track door rail roll forming machine