The ladder type cable tray made by roll forming machine, it improves the flexural capacity of whole bridge. There are ribs on the side and underside, make the cable tray beautiful in appearance and has high load capacity. Noramlly the size is around:

Maximum thickness 2mm, Ladder length is 2 meters, 6 meters long span. If there is specail, the cable tray also could be customized.

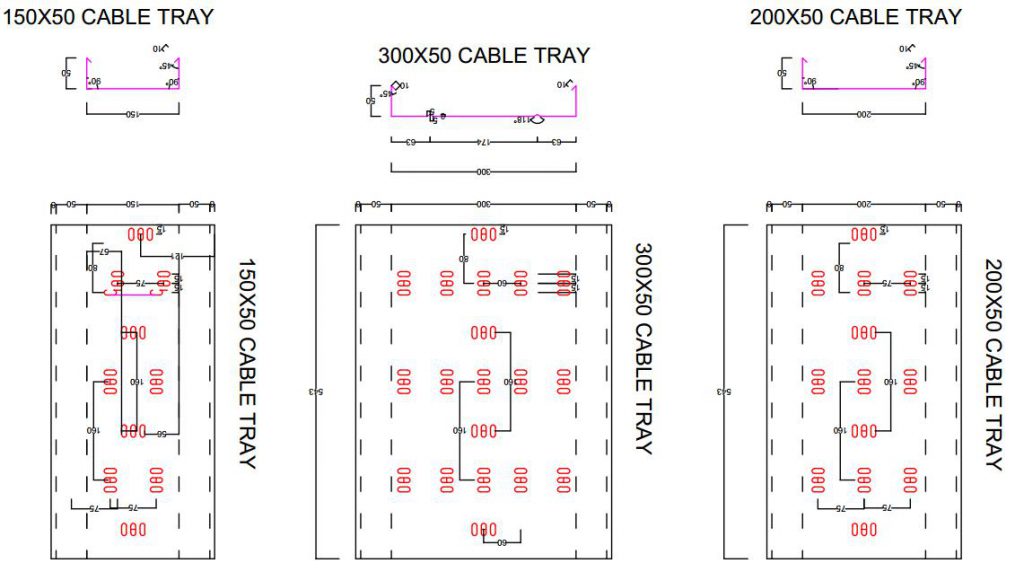

Here are some simple cable tray drawing profiles for your reference:

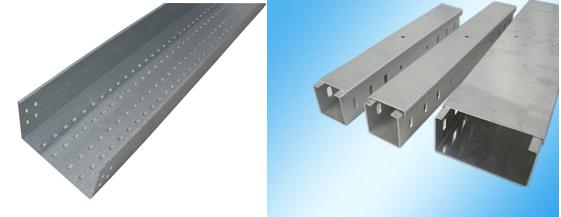

Finished product samples made by our machine:

Based on the design, we make machine like the following:

Main elements of ladder type cable tray roll forming machine:

| NO. | Item | Description |

| 1 | Decoiler | Hydraulic, mnual or motor (customize) |

| 2 | Leveling Part | Guarantee that the products are neat |

| 3 | Punching and shearing part | This part will punch material to the type as customer required. |

| 4 | Roll forming machine | Check detail below |

| 5 | Hydraulic Station | Hydraulic tank, a set of hydraulic oil pump, two hydraulic pipes. and two sets of electromagnetism valves |

| 6 | Electric Control System | Adopted PLC, transducer, touch panel from Delta Taiwan to ensure high speed with stability, precision and lifetime. |

Main ladder cable tray machine roll forming machine parameters:

Feature: Ensure the stability, accuracy and long life.

Voltage: customize by customer.

Method for fixing roller: arch type.

Material of shafts: 400# I-beam

Transmission method: gear box

1). the main shaft material: No. 45 steel quenching and tempering treatment, the outer shaft diameter is90mm

2). Wheel material: quenching process of GCr15 bearing steel HRC58-60

3) Roller: 20 stations.

4). the main motor power: 22kw

5) Forming: 12M per minute.

Why choose ladder trype cable roll forming machine:

1.Sizes are adjustable, no need to change spacer, all fully automatic.

2.Accuracy could be guaranteed. High quality punching and shearing system.

3.No need to change shearing blade: post shearing system, so no need change or adjust baldes for different sizes.

4.Pillar stand, fast speed and long time to use.

For this machine, if you want to know more information, please contact us at any time.

Next: The gear box transmission and hydraulic cutting system door frame roll forming machine