How to do punching fast to match rolling forming machine?

For some special drawing profile with punching holes, we need to do the rolling forming also; some times the working speed can not be fast. By the normal punching machine, the working speed Maxium 25m/min and then together with the rolling forming, the working speed is around 15m/m/.

For those who bought the machine in high speed like 50m/min, if you use the normal punching machine, it will be totally wasted. So here in this article, I will show you one rotary punching machine; the working speed could reach 100m/min. By this way, the working speed the rolling forming machine could reach at least 50m/min. And then working efficiency could be enhanced greatly.

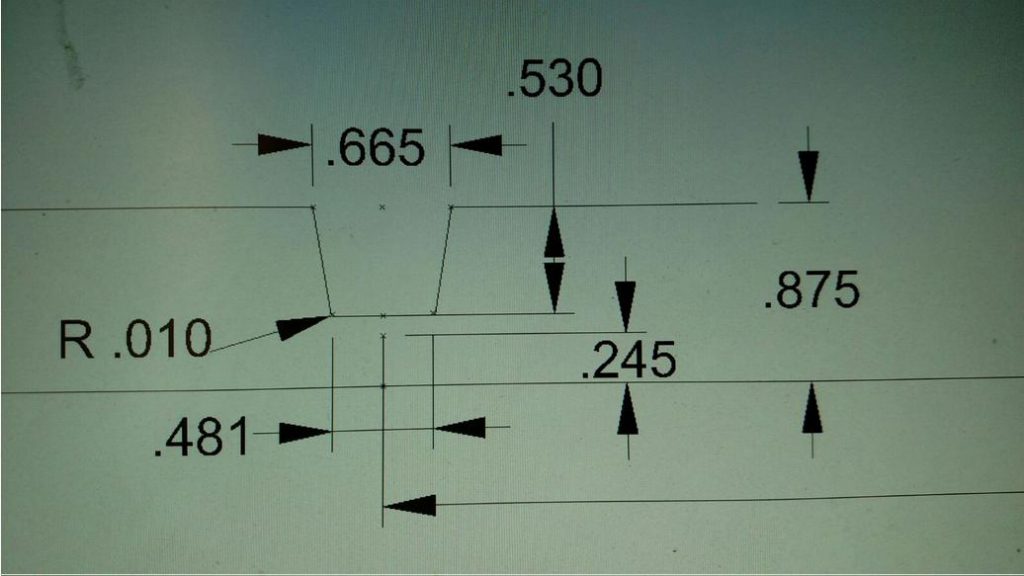

Taking a random punching for example, here I will introduce rotary punching machine briefly:

Here are the rotary punching machine paramters for your reference:

| Supported Max thickness | 0.64mm to 1.5mm |

| Supported material coild width | 22.22mm to 50mm |

| Working speed | 0 to 100m/min adjustable |

| Notching pitch | 195.2mm |

| Feeder length | 0~9999.99mm |

| Accuracy | ≤0.2mm ±1%. |

| Electricty | 220/ 440V 60hz,3PH |

| Motor power | 2.5 kw |

| transducer | 3kw |

| reducer | speed ratio 40 corner |

| Feeding coil direction | From left to right |

| Machine size | 2000x1600x1300mm |

| Weight | 2000KG |

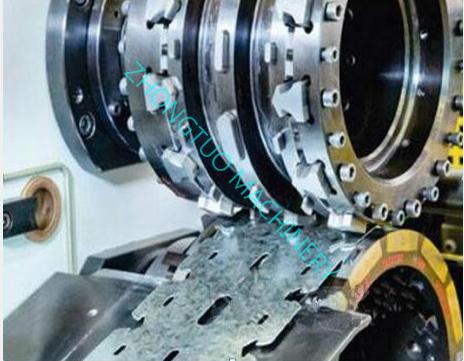

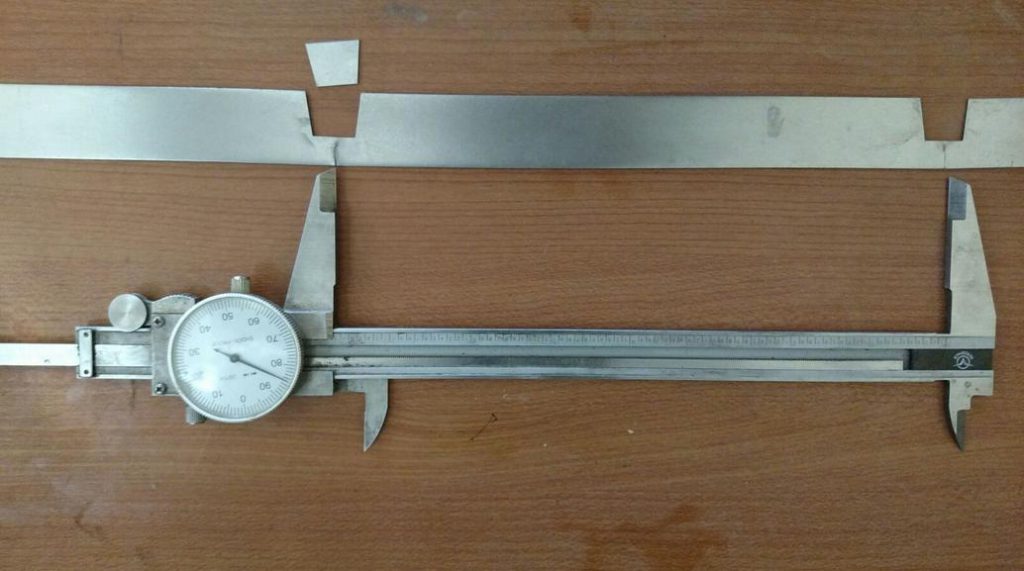

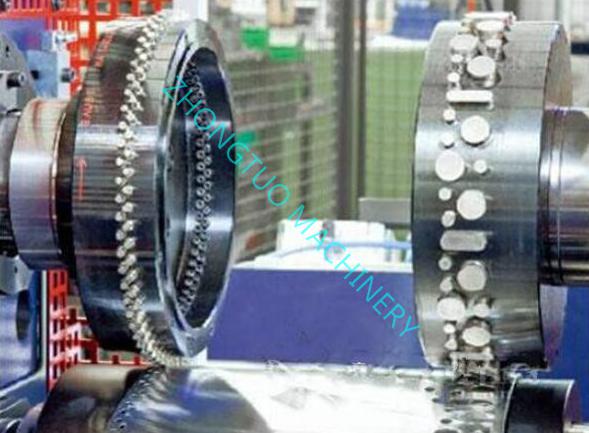

Machine pictures for your reference:

This type rotary punching machine can help you enhance the woring production greatly. And simple change the punching molds, you can make it any type of punching holes.

For this rotary punching machine, if you need to know more, please contact us at any time.