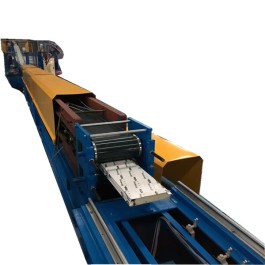

Roll forming for garage door panels and garage door track, all machines we can do for you.The whole process for manufacturing insulated garage doors and track is from the uncoilers to leveling beach, roll forming, shearing and then runout table.

Firstly we check for the Garage shutter door features:

1.The garage shutter door material thickness is from 0.8 to 1.5mm.

2.The height of the shutter door could reach 9 meters -14 meters.

3.Maximum wind resistance reached 11.

4.Surface treatment technology: electrostatic powder spraying, anti-corrosion, anti scratch, easy to clean, long lasting color. The surface paint processing, durable weather resistant to sunlight, rain resistance, corrosion resistance and scratch resistance in minor collisions.

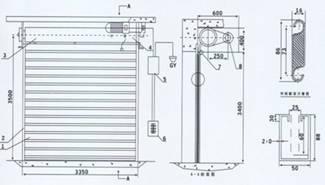

Based one garage shutter door features, we give drawing and machine design for referemce:

Here is the garage shutter door machine design for your reference:

Main parameters of garage door roll forming machine:

Main machine:

a. Number of forming steps: 14 stations

b. Shaft material: 45# steel with quenched treatment, precision machined,

The diameter: ¢56mm

c. Roller material: bearing steel with quenched treatment

d.Transport: by gear

e. Forming speed: 10-25m/min

f.Motor:5.5kw

g.Voltage:380v, 50Hz,3 phase

h.Structure: independent stand

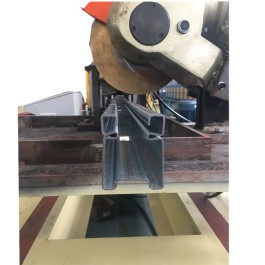

For shearing system:

1.Servo flying and tracking cutting saw, the cutting saw will adjust the cutting speed and location according to the main machine speed. By this method, the machine working speed will be same as the main machine accordingly. The cutting plate we take the best material for cutting it in high speed and beautiful cutting scare.

2.The material of blade: Cr12Mov, HardeningHRC 58-62℃

3.Length Tolerance:3m±1.5mm

Now check how the garage door installed:

For this machine if you want to know more information, please contact us as soon as possible.

Next: Half automatic door frame & window frame rolling forming machine