Description

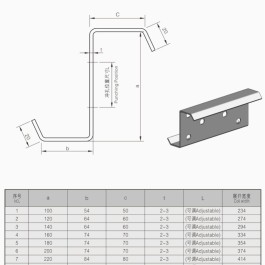

Fully automatic C and Z purlin roll forming machine can produce C and Z purlins with different sizes of 80-300 mm, two sets of punching, and raw material thickness of 1.5-3.0 mm, which basically meets the needs from different countries.,and if client have more requirements,we can customize the machine for him.

The machine is installed and commissioned before leaving the factory. After receiving the machine, the customer can start production as long as the wiring and tubes connected . instructions send to tell how to operate. Of course, we also have corresponding videos for reference. our technicians are available to guidance and training in your factory if necessary

1. The small size of Z purlin made by special design is less than 120mm, very straight and not twisted. Generally, the small size of Z purlins made by other factory is not straight and will twist.

2. A 75 mm solid shaft is used, and the H-shaped steel is used as the base frame, so that the machine can withstand long-term production without deformation of the machine, thereby ensuring long-term production of quality purlins ;

3. The rollers are GCR15 material and processed by CNC machine tools to ensure the accuracy of the rollers, and thus the accuracy of the final purlins.

4. Our cut frames are stress-relieved to ensure that they are not deformed during the long-term production process, making c purlin smooth.

5. Use Mitsubishi or Siemens operating system with stable performance, simple operation, Once input length and quantity , purlin forming machines are automatically produced , and the cutting length tolerance is within ± 2mm

6. Forming speed can reach 10-15 meters per minute.

Main Technical Parameters

| Roller stations | 13-16 rows |

| Diameter of shafts |

75mm |

| Forming speed | 15m/min |

| Roller material | GCR15 steel,quenched treatment |

| Cutter material | Cr12 steel,quenched treatment |

| Control system | PLC control |

| Main motor power | 18 KW |

| Hydraulic power | 5.5 KW |

| Voltage | 380V/50HZ/3P(as requested by clients) |

APPLICATION

Purlins are quite popular these days and are available in different shapes and sizes, most commonly use as C purlins and Z purlins.

Zhongtuo machinery factory make Purlin forming machine, which can produce both C and Z in the same machine, only need minutes to change between C and Z.

Besides, Purlin machine can produce size between 100-300 with easy adjustment, which take only ten minutes.

Important, our purlin machine can design with punch device with function of punch holes on purlin for screwing during installation.

Operate easily , work automatically with PLC controller control.

Decoiler- forming- punch – cut – run out

Next: Take care of your roll forming machine