Door frame roll froming machine could be used to make metal door in various types in batch fully automatically. Door frame roll froming machine can produce plastic window steel liner, door lining steel, which can realize the production of a variety of plate type machines. It has features of high efficiency, good linearity, and good consistency.

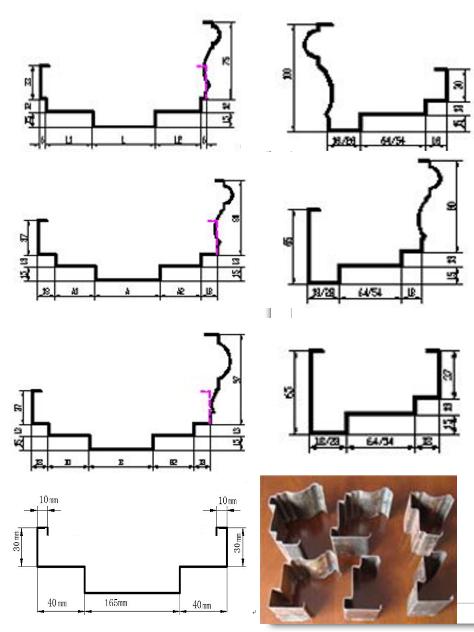

Normally speaking, the door frame material could be various types to make the whole door style beautiful and fasionable. In the market, most of the metal door frame could be made by cold roll froming machines. I can not list all of them here, just take some drawing profiles for your reference:

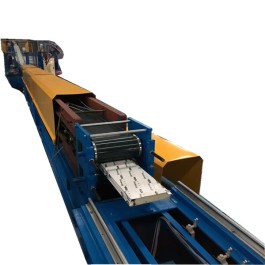

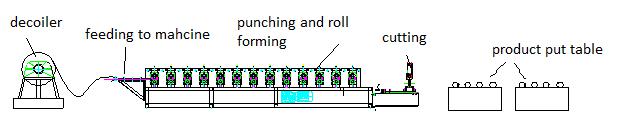

Here is the machine working process:

Decoiler---Feeding to the machine----Roll forming part and -Punching ----Cutting part----Product out table

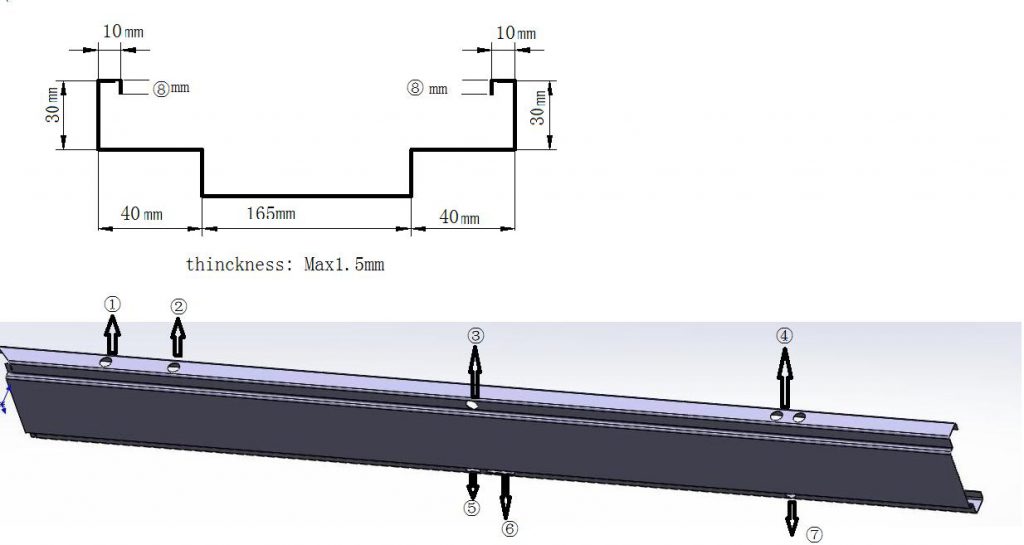

Take the following door frame drawing profile for example:

Main parameters of the roll forming machine:

1: Coil width: according to the profiles

2: working speed: 5-12m/min

3: roll station: 19 stations

4: material of roller: GCr15 quenched 58-62°

5: material of main shaft: 45﹟forge steel

6: main power: 15KW.

7: forming thickness: Max 1.5mm

8: Transmission: chain

9: size of machine: about 11800×2200×1500 (mm) L x W x H

10: weight: about 8.5Ton

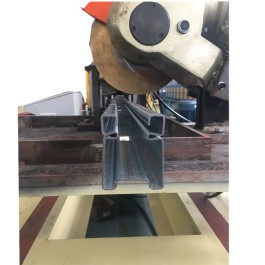

For the sheaing system:

1. Hydraulic working pressure: 20Mpa

2: Cutting after forming: Cut the sheet

After roll forming to required length

3: Material of blade: Cr12 with heat

treatment 58-60°

4: Length measuring: Automatic encoder

Length measuring, brand: Omron

5: Tolerance of length: 3000mm+/-1.0mm

6: Cutting table length: 0.3m-10m

For the door frame machine, if you want to know more information, please contact us at any time.

Next: Door frame roll forming machine with Gear transmission and non stopping cutting system