Characteristics of C-section Steel Machine Equipment

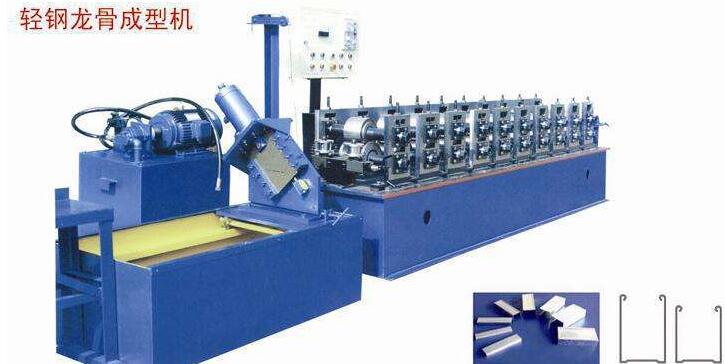

C-type steel machine mainly consists of passive charging frame, leveling device, punching device, cutting device after forming, hydraulic station, computer control system, etc. This machine adopts automatic flying saw punching, easy to operate and so on. The main use products can be used as the main force structure of large and medium-sized industrial and civil buildings.

C-type steel machine, also known as C-type steel sandalwood machine, is one of many kinds of tile press, is a basic type of tile press. Unlike the color steel plate forming machine, it is hydraulic power, and power is very large, generally around 22KW, similar to the shear bending machine, the general control process is complex, mostly using PLC control. Process flow of C-section steel machine equipment: strip is fed from the tail of the equipment and pressed into C-section steel by various rollers from the head. In traditional technology, C-section steel needs to be cut off manually after pressing, and then transported to punching equipment to punch according to the size required by customers. The production can not be continuous and the efficiency is not high.

C-section steel belongs to high-efficiency and economical section (other cold-formed thin-walled section steel, profiled steel plate, etc.). Because of the reasonable cross-section shape, they can make the steel more effective and improve the cutting ability. Unlike ordinary I-shaped steel, the wing embroidery of H-shaped steel is widened, and the inner and outer surfaces are usually parallel, which makes it easy to connect with high-strength spiral cassia and other components. Its size constitutes a reasonable series with complete models, which is convenient for design and selection. C-type steel machine, also known as C-type steel sandalwood machine, is one of many kinds of tile press, is a basic type of tile press. Unlike the color steel plate forming machine, it is hydraulic power, and power is very large, generally around 22KW, similar to the shear bending machine, the general control process is complex, mostly using PLC control. C-beam mill is a single-coil forming unit which can produce various specifications of C-purlin products by rolling rolls. The machine mainly consists of passive charging frame, leveling device, punching device, cutting device after forming, hydraulic station, computer control system, etc. This machine adopts automatic flying saw punching, easy to operate and so on.

C-type steel machine can be used as the main force structure of large and medium-sized industrial and civil buildings. The upper die and six lower dies of the same specifications and sizes are required for the die used in the C-beam machine. First, the upper die and the lower die are installed directly on the hexagonal runner table.

The upper die is installed on the bottom of the slide seat, and a cushion plate with appropriate thickness is placed to ensure that the clearance around the upper and lower die is uniform, and the distance between the upper and lower die is equal to the thickness of the required tile blank. Then the upper and lower dies shall be taken as the standard, the worktable shall be rotated, and the other five sets of lower dies shall be installed. After all the upper and lower dies have been installed, the tile can be driven. The improvement process is completed in three steps. The first step is to improve the length measuring device and the flying saw. When the pressing length reaches the set length, the flying saw moves and cuts the profile automatically. The second step is to add a hydraulic punching device to punch four holes at the same time, and the flying saw cuts off the middle, thus forming two side holes at the head and tail of two adjacent sections of C-section steel. In the third step, an additional equipment for punching holes is added to punch out the holes according to the user-set spacing in the process of strip pressing. The maximum number of holes can be punched is 16. In the fourth step, aiming at the requirement of punching double holes in the middle of profiles for new C-section steel, the 4-hole punching die with side holes was changed to 2-hole punching die, and the program of punching side holes was modified so that the punching equipment with side holes could punch double holes in the middle, and the hole spacing was set by users, and the maximum number of double holes could be punched 8 groups. Foshan Teruixin Machinery Equipment Co., Ltd. is the preferred manufacturer of C-type steel machine. The company specializes in the production of cold bending forming machines such as coiling gate machine, keel machine, door frame machine equipment, color steel tile machine, greenhouse slotting machine, etc.

We also have shutter door slatsroll forming machine for your reference. And you also can contact with us at any time.