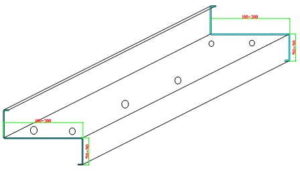

Z purlin roll forming machine

Z purlin roll forming machine works in the same principle as a c purlin roll forming machine does for producing steel purlins for metal building systems, only the purlins’ shapes make difference.

Z steel purlins can be used for a variety of applications, but 90% for steel structural building system, and 10% for other usages (some people use z steel purlins as the supporting clip inside sandwich panels, while some others put z steel purlins on a samples racks etc).

Brief data of the z purlin roll forming machine

Like c purlin roll forming machine, z steel purlin roll formers also is designed to produce the section channels of different sizes, but the change to make a different size z purlin is manual. Clients need to manually change the spacers installed between rolling tools, as well as the cutting dies.

Forming stations:20

Roller material: GCr15,heat treatment and hard chromer-plated, HRC55-58

Shaft material: S45C, heat treatment HRC42 with diameter is 80 mm

Punching hole: before forming

Forming speed: 18 m/min

Main motor power: 15 kw

Control system: PLC

This type z purlin roll forming mahcine is suitable for the following situations

1. Production rate is high

2. Your country worker salary is high

3. You need the fully automatic Z purlin roll forming machine

4. Save the cost of professional workers to adjust machine

5. Save the workers cost of running machine

6. Save time of changing sizes

7. long time to use machine

8. You need gearbox as machine transmission method

9. You need to change the sizes within 5 minutes

10. You need machine usage time is around 10 years or more