Z purlin making machine

Z purlin can attach roofing sheets or wall cladding. Our z purlin making machine can make z purlins and ensure ultimate durability. I will introduce more detail information about the machine in the following.

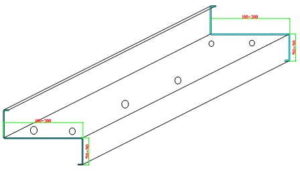

A drawing profile of z purlin

Picture and parameters of the Z purlin making machine

| Forming steps | 19 rollers |

| Shaft diameter | 90 mm |

| Design type | Middle plate welded |

| Machine frame | 400# H steel welded |

| roller material | GCr12 steel |

| shaft material | 40CR |

| Work speed | 15 m/min |

| Transport | By chain |

| Power of main machine | 18.5 kw |

| Type of cutting | Hydraulic |

| Cutting tolerance | ±1mm |

| Cutter | Gcr12 |

| Cutter quantity | 1 set |

| Working pressure | 20MPA |

Manual decoiler

| Inner Diameter:450-550mm | Expand by manual |

| Outer Diameter: max 1500mm | |

| Max Coil width:500mm | |

| Capacity: 5T |

Hydraulic system

| Hydraulic oil | 46# |

| Hydraulic power | 5.5 kw |

| Cutting length | As required |

Control device

| control | By PLC |

| PLC language | English and Chinese (or as required) |

| Touch screen | 4.7 Inch |

| Function | Automatic length and quantity measurement |

Other spare part

| Weight | About 7.2 ton |

| Dimension | 7800*1600*1500 (mm) L x W x H |

| Main body color | Main body color |

| Voltage | 380v/50hz/3ph(or as required) |

| Spare cutting blade | One piece for profile |

| Fuse | 2 pieces |

| Relay | 2 pieces |

| Travel switch | 2 pieces |

| Solenoid valve | 1 pieces |

The application of z purlin

Purlins are horizontal beams that allow you to safely attach roof sheets to the building. They sit between the sheet and the building, acting as a support for the sheet. This ensures that the roofing is firmly attached and safely in place.