Steel slitting line

Metal sheets or strips suppliers always need slitting machine and cut to length machine line for the production of metal sheets with different widths or lengths from GI, PPGI or stainless coils in large quantities. A steel mill most of time produces only wide steel coils, and steel or metal fabricators always use a slitting and cut to length machine line to manufacture steel strips with different widths or metal sheets with fixed lengths. A steel slitting line has been designed to cut longitudinally the wide steel coils into different narrow steel strips for continuously producing cold formed sectional steel products.

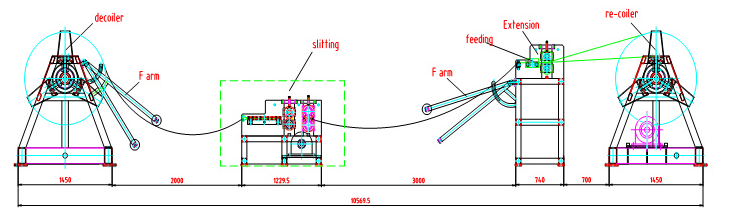

Layout of complete line

Technical parameters of steel slitting line

Raw material specifications:

Raw material: GI or PPGI

Thickness: 1—5.0 mm

Width: small than 1250mm

Inner diameter: 500mmmm

Max out diameter: 1500mm

Max weight: 10 T

Finished product specifications:

Width tolerance: 0.5mm

Min slitting width: 30mm

Decoiler specifications:

Max coil weight: 10 T

Inner diameter: 500mm

Max out diameter: 1500mm

Power: 7.5KW

Decoiler speed: 0-30m/min

Slitting device specifications:

Slitting speed: 0-30mm/min

Driving motor: 3.0 KW

Slitting shaft diameter: Ф100mm

Shearing blade: 12 pieces

Max slitting pieces: 12 pieces

Min slitting width: 30mm

Shearing blade material: 12CrMoV

Pinching roller: 2 couples

Power: 22KW, 380V 50HZ, 3 phase