Steel Guardrail Roll Forming Machine

Steel Guardrail Roll Forming Machine

Introduction

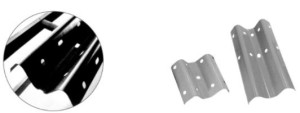

Express road guardrail panel is made from hot rolled steel strips,and straightened,holes punched,roll formed,and cut to length by guardrail roll forming machine. The finished products are of many features. Such as high efficient,high automation,less labor.and etc.This machine integrates the technologies of cold roll forming,punching,automatic stack,and automatic controlling.

The guardrail roll forming machine consists of uncoiling system,straightening system,scrap edge cutting,leveling guillotine shearing system,holes punching system,cold roll forming system,cutting to length system,automatic stacker system,electric controlling system,hydraulic system,automatic controlling system,and so on.

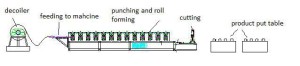

Working Flow

Uncoiling-Sheet Guiding-Straightening&Leveling-Scrap Cutting-Holes Punching-Roll Forming-Cut to Length -Sheet to Support Table

| Item | Parameters | |

| Profile | Two ribs and three ribs guardrail | |

|

Material |

Type | Steel strip |

| (mm)Thickness | 2.5-4.0 | |

| (Mpa)Yield stress | 230-300 | |

| (m/min)Max.Forming speed | 20 | |

| Roller material | D2 | |

| Roller driven type | Gimbals transmission | |

| Controller | PLC | |

| Operation | Touch screen+button | |

| (Mpa)Hydraulic system pressure | 25 | |

| (kg)Total weight | About 50000 | |