Shutter door roll forming machine

Shutter door roll forming machine

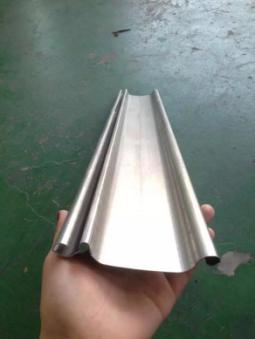

Shutter door is made by slats connected together,widely used in business door,garage door,shopping mall,hospital,it has many features,auch as esay,and fast, very convenience.Shutter door roll forming machine is our hot sales machines.We have exported shutter door roll forming machine to many countries. Our shutter door machine can produce different size of shutter slats,realized by change the molds,not only can save the cost, but also save the space.

1.Basic technical parameters of material

Thickness:0.8-1.2mm

Coil weight:Galvanized steel

2.finished product

3.Main technical specification of equipments

3.1 Decoiler

Usage: It is used to support the steel coil and uncoil it in a turntable way.

Passive uncoil pulled by roll forming system.

a. Coil inner diameter: 450-550mm

b. Coil max width: 300mm

c. Max carrying capacity: 3000kg

3.2Entry leveling

This part will level coil to make sure it is neat clean and straight.

3.3roll forming machine

a. Number of forming steps: 12 stations

b. Shaft material: 45# steel with quenched treatment, precision machined,The diameter: ¢50mm

c. Roller material: Gcr15 with

quenched treatment

d. Transport: by gear

e. Forming speed: 5-15m/min f.Motor:4kw

g.Voltage: 380V 50Hz 3 Phase

h. Structure: independent stand

i.Size of machine:4.5m *1.2m *1.4m

j.weight:3.6T

3.4Shearing system

The material of blade: Cr12Mov, Hardening HRC 58-62℃

Length Tolerance:±1.0mm