Roller shutter door roll forming machine

The roller shutter door slat roll forming machine is a simple and flexible production line manufacture of various kinds of metal shutter slat profile for metal door industry.

The roller shutter door slat roll forming machine is available to produce different kinds of roller shutter slat profile in cutomer design, there are many kinds of roller shutter door slats, such as the flat slat, curved slat, perforated slat. For different product volume requirements, a flying-cut and double end decoiler also can be integrated. For perforated slats, a high speed coil punching line is available in-line or out-line operation.

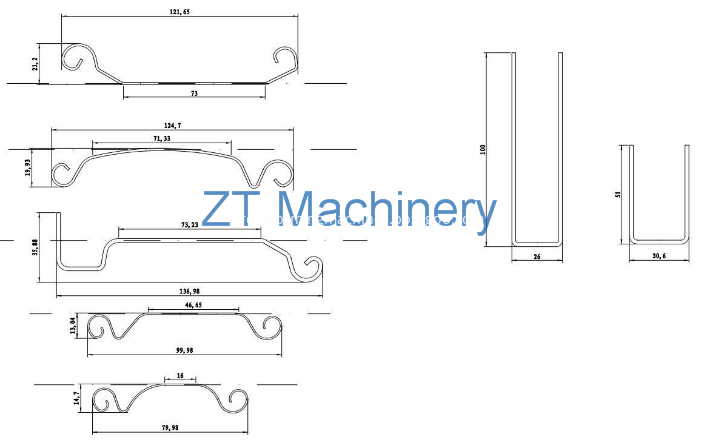

Check some profiles of roller shutter door slat

Parameters of roller shutter door slat roll forming machine

| Working efficiency with punching | 12 m/min | ||

| Thickness of Material | 0.8 to 0.8 mm | ||

| Control system | PLC | ||

| Uncoiler system | 3 Ton manual expansion | ||

| Forming by rolling | Roll 14 Roller station | ||

| Roller material | Gcr15 quenched | ||

| Shaft and the diameter of axle | 45#Aluminium processing diameter of axle=¢50mm | ||

| Main part power | 4 kw | ||

| Hydraulic motor power | 3kw | ||

| Hydraulic pressure | 20Mpa | ||

| Scissor material | Gcr12MoV quenched | ||

| length tolerance | ±1.0mm | ||

| voltage | 380V, 50HZ,3 phase | ||

| Driving Method | Chain | ||

Features of struct channel roll forming machine

1. material with galvanised steel, pre-painted steel or aluminum thickness from 0.8-1.2 mm

2. production speed of struct channel roll forming machine is 20-25 m/min

3. automatic "hands-free", PLC control system with touch screen

4. cut to any length by setting on touch screen in PLC system

5. stationary hydraulic cut off make accurate and clear cut

6.in-line punching press is equipped for hole slooting

7. option with flying shear to maximum product output

8. option with multi-profile roll tooling designing for product size changeover

9. option with auto-stacker to minimize operator cost