Roll Forming Machine for Two Waves Road and Highway

Roll Forming Machine for Two Waves Road and Highway

Highway Guardrail Roll Forming Machine

- Brief Introduction:

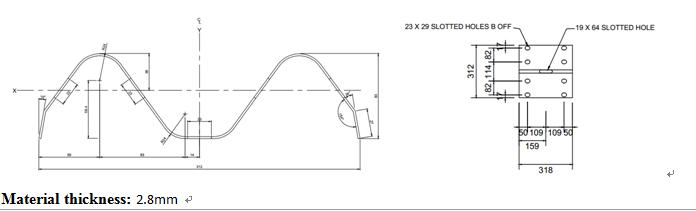

- Production Drawing: (as per the final drawing)

- Product size can also be custom-made according to customer's requirement.

- Parameters of the raw material:

| Material | Thickness | Width | I.D. | Max. O.D. | Yield strength | Max. coil weight |

| Galvanized steel | 2-4mm | 510,780mm | Ф508 mm Ф610 mm |

Ф1500 mm | 350 Mpa | 5T 10T |

- Main Technical conditions of the production line:

- Temperature: -15ºC~40ºC

- Voltage: 380/480V± 10%, 50/60 HZ, 3 P

- Air pressure: 0.6~1.2 Mpa

- Total gas: 200 L/min

- Total power: ≈75 KW

- roller material: D2,Cr12

- Color:

| Main body | Protective cover | Main moving parts | Protective nets |

| RAL5015 | RAL3020 | RAL1016 | RAL9017 |

- Production capacity: 15m/min

- Dimension (L*W*H): L≈ 35m, W≈ 2 m, H≈ 2m

- Specification of the shipping container: (The number is pre-estimated ≈, final data should be confirmed in two weeks before delivery.)

| Container | 40GP | 40OH | 40OT | 20GP | 20OH | 20OT |

| Number | 3 |

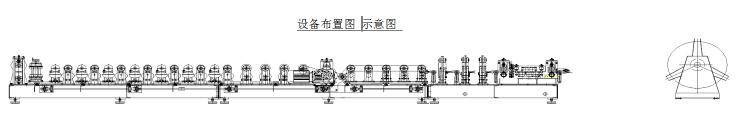

- Working Flow:

- Decoiling → Leveling → Shearing & Butt-Welding → Feeding Material → Punching Hole → Pre-cutting → Roll forming → Plates to automatic stacker

- Components List:

| No. | Components Name | Description | Quality Set/piece |

Mark |

| 1 | Decoiler | Hydraulic Decoiler | 1 | |

| 2 | Leveling Device | 5 Rolls Levelling | 1 | |

| 3 | Shearing & Butt-Welding | 1 | ||

| 4 | Loop Device | 1 | ||

| 5 | Servo Feeding Device | Drive by Servo Motor | ||

| 6 | Punching and pre-cutting Device | Punching Hole and pre-cut the sheet to fixed length | 1 | |

| 7 | Guide Feeding Device | Vertical Roll Guide | 1 | |

| 8 | Roll Former | Individual Roller Station | 1 | |

| 9 | Automatic stacker | 1 | ||

| 10 | Hydraulic System | Dedicated System | 2 | |

| 11 | Electric Control Section | Control Production Line | 1 | |

| 12 | Remote network system | 1 | ||

| 13 | Spare Parts | 1 | ||

| 14 | Manual of the machine | 1 |