Metal stud roll forming machine

Metal stud roll forming machines are the main type of machine for producing these steel framing studs. Also called stud and track rolling machines, a roll forming machine can run at high speed and produce as much metal studs as is required. Studs are shaped little by little as they move through the stations of the roll forming machine. When they reach required length they are cut off with a flying-cut off. As the studs move through the roll forming machine holes can be punched at required intervals. I will detailly introduce the metal stud roll forming machine for you.

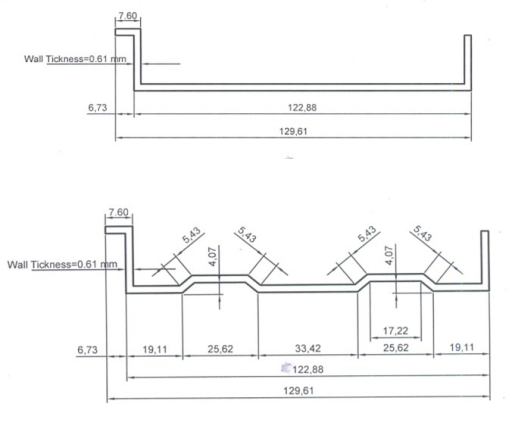

The drawing profile of metal stud

Coil material thickness:0.61mm

Need seeds

Material:PPGI,GI

The parameters of metal stud roll forming machine

Studs are shaped little by little as they move through the stations of the roll former. When they reach required length they are cut off with a flying-cut off. As the studs move through the roll former holes can be punched at required intervals.

Manual Decoiler

1).Material coil inner diameter: 450mm-550mm

2).Max coil Width:400mm

3).Carrying capacity: 1.5T

Forming system

1).Roller station:10stations

2).Shaft material:45# steel

Outer diameter:40mm

Roller material: GCr12MoV

3).Transport: Gear Driving

4).Forming Speed: 25 m/min

5).Motor:3kw

6).Size of Machine: 5mx1.2mx1.45m

7).Weight:2.2T

8).Voltage:380v,50Hz,3 phase

9.The test material:PPGI,GI

The similar photo attached as follow:

The video of metal stud roll forming machine