Metal stud furring channel roll forming machine

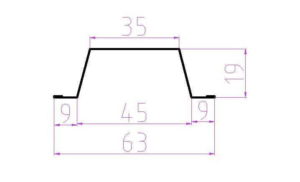

The metal stud furring channel roll forming machine has been designed for the manufacturing of hat shaped furring channels. And the hat shaped furring channels used to build lightweight or light gauge steel buildings.

Being one of the roll forming machines for the production of lightweight or light gauge steel frames, a stud furring channel roll forming machine or hat channel roll forming machine produces metal furring channels or hat channels continuously and automatically from galvanized steel of 0.4-1.0mm thickness as main components of steel roof trusses on lightweight or light gauge buildings.

On a heavy gauge metal or steel structural building, people always use C steel purlins or Z steel purlins to build the steel frames and roof trusses, while Metal furring channels or roof channels climb to the top of components lists for roof trusses of lightweight or light gauge steel frames.

The metal furring channels or hat channels are produced from thin galvanized steel (0.4-1.0mm thickness) by roll forming machines and a metal furring channel or hat channel roll forming machine, like other lightweight or light gauge steel frame roll forming machines, generally consists of a manual decoiler, a feeding unit, an embossing rolling tool, a roll forming unit, a cutting unit, a transmission system, a cutting unit, a hydraulic oil pump, a PLC control system and runout tables.

The followings are some brief information about the metal stud furring channel roll forming machine

Roll station: 14 stations

Motor power: 3+3 kw

Productivity: 0.-25 m/min

De-coiler capacity:1.5 Tons

PLC brand: Delta or customized

Cutting type: automatic hydraulic

Hole &LOGO is available

We also can customize the metal stud furring channel roll forming machine, please feel free to contact with us.