CU prulin making machine

As the main force part in the construction, our CU purlin making machine can make different sizes CU purlin for you. This CU Purlin making machine, can produce C shape and U shape purlins from 100-400mm of width and easily to change spacers. Maximum thickness can be formed at 1.5-3mm. Also we can design this machine to work with any width of the purlins and main channels, automatically adjustable by PLC control or adjust handle wheel to change the sheet width.

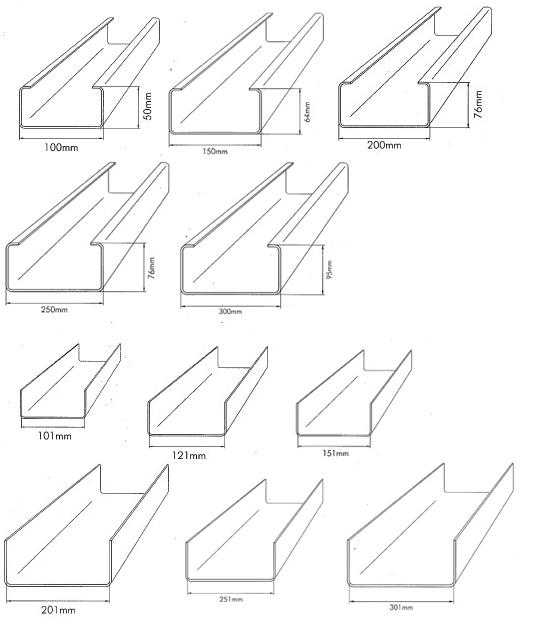

The drawings of CU purlins

Main components of CU purlin making machine

Hydraulic uncoiler

1). Inside diameter coil is 450 - 550mm

2). Coil Width is 600 mm

3). Capacity:5 ton

5). Hydraulic expansion

6).Automatically feeding

7). Hydraulic, inner tight

8).Hydraulic power: 3 kw

Main forming system

1).Roller station:12 steps

2). Roller material:GCR12 Mov

3) .Shaft material:45# steel,Outer diameter: 80mm

4) .Transport:Transport by Gear

5).Forming speed: 8-10m/min

6) .Motor:22kw

7).With yellow safety guards

8) .Voltage: 415v 50hz 3phase

Cutting system

1).Blade and mold material: Cr12 steel with quenched treatment

2).Cutting system:advanced hydraulic drive, automatic cutting

Control system

PLC control

Hydraulic system

1). Advanced hydraulic system

2). Power:7.5kw

Punching

Punching hole as drawing

Warranty

1).One year, and we will provide the technical support for the whole life.

2).Training: the buyer should charge of visa, return ticket, food and accommodation overseas and USD100/person/day for salary.