C shaped section channels roll forming machine

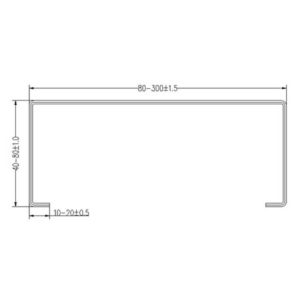

C shaped section channels roll forming machine is an equipment that produces C shaped steel channels continuously out of galvanized or cold rolled steel strips from feeding, punching for holes, bending and cutting.

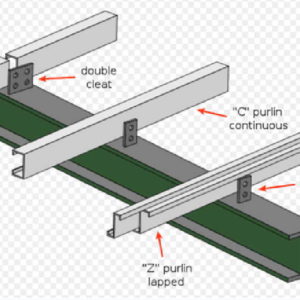

Nowadays, people developed stone or concrete purlins which were strong enough to hold a house for long time. However, the builders and house owners find that the owners have to spend much more money than using wood purlins; and that the builders must spend much more time than using wooden purlins. Therefore, entering into modern ages, the stone or concrete purlins becomes the last choice for industrial or some individual buildings.

Compared to traditional purlins, steel purlins have so many advantages, they are light, easy to install, and recyclable for other buildings etc. Therefore, as we can see, in mordern steel industrial buildings or prefab enineered buildings, people always use C purlins, Z purlins and sometime U purlins without flange stiffeners as well.

Brief details of c shaped section channels roll forming machine

Forming steps: 16 rollers

Shaft diameter: 90 mm

Design type: Middle plate welded

Machine frame: 400#H steel welded

Roller material: Gcr12 steel

Shaft material: 40CR

Working speed: 15 m/min

Transport: China

Power of main machine: 18.5 kw

Type of cutting: hydraulic

Cutter: Gcr12