c purlins roll forming machine produce sizes

c purlins roll forming machine produce sizes

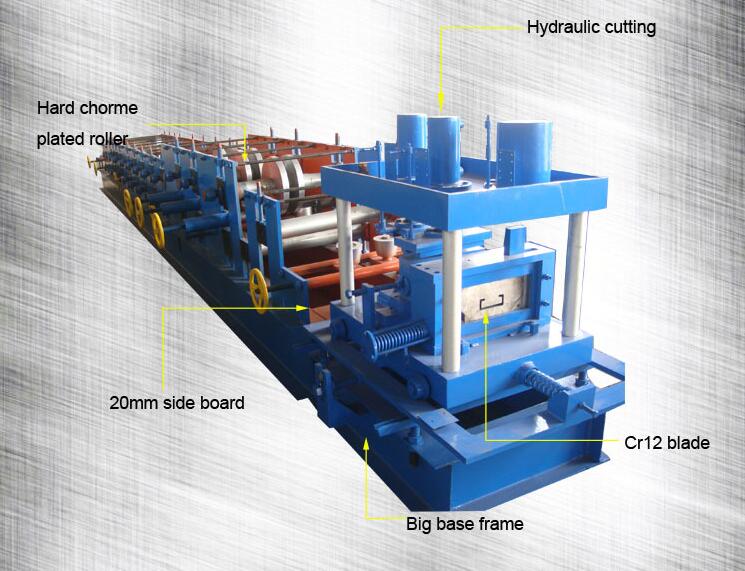

| Automatic c shape purlins roll forming machine,c purlin forming machine | Model | Shibo-roll forming machine |

| Forming size | 9000mm*1600mm*1400mm | |

| Weight | 4.5 T | |

| Host big frame structure | Frame welded | |

| Roll station | 12row | |

| Axial material | 45# steel | |

| Out diameter of shaft | Φ80 | |

| Roller materials | 45# steel hard chromium plating | |

| Drive | By chain | |

| Sprocket chain | 2inches | |

| Main power | 15kw | |

| Working speed | 8-10 m/min | |

| Material thickness | 1-3mm | |

| Made board | 20mm | |

| Feeding width | 1200mm |

B. Advantages:

C-purlin machine and Z-purlin machine Series

The C and z purline formed by this purline forming machine has many advantages: Well compressive strength and flatness; Automatioc measureing, cutting and punching; High-level of automation and conviently installation.

C. Usage

It can be used in the main body stress structure of the large and medium-size enterprises civil construction, like the plant, the warehouse, locomotive shed, hangar, exhibition building, theatre, stadiums, roofing load-bearing load and wall surface support of the arbour.

This machine is composed of manual stacker, feed leading table, flattening device, main froming part, punching system, flat cuttingsystem, hydraulic station, computer control box.

Here are some pictures of C purlin forming machine

C Purlin Forming Machine can produce many standards of C Purlin. Please look at the above chart.

D. Terms

Payment type: 30% T/T prepaid and balance should be paid before loading

Delivery time: 30days after receving advance payment.

Guarantee period: 12months

E. Installation and training:

If buyers visit our factory and check the machine, we will teach you how to install and use the machine, and also train your workers/technician face to face.