C purlin machine

With the adoption of PLC control mode and AC variable-frequency speed regulation technology, our C purlin machine is high efficient for continuous producing purlines. Its raw materials are coiled steel sheets and its main components are decoiler, guiding system, leveling system, pre-cutting system, roll forming system, electric controlling system,hydraulic system, and bracket.

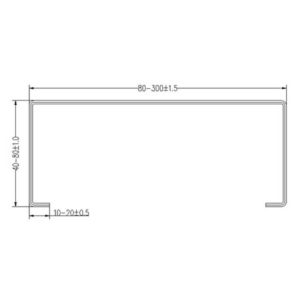

Some pictures of the c purlin machine

Features of C purlin machine

1. This machine is made up of welded steel. It uses processing technology to protect its integrity.

2. It has rational structure, strong carrying ability, and stable performance.

3. This machine has high forming precision and long service life because it undergoes high precision processing and heat treatment before chromeplate.

4. Components from famous brands ensure the whole performance and quality of our machines.

5. The C purlin machine can be operated by workers without special training because of its PLC control mode.

6. Easy to debug, low noise and high efficient.

Parameters of c purlin machine

| Forming station | 14 stations |

| Forming Rollers | GCr15, heat treatment and hard chrome-plated ,HRC55-58 |

| Main shaft material | S45C, heat treatment HRC42Φ80mm |

| Leveling roller | 5 rollers |

| Cutting sheet | Cutting after forming, stop to cutting |

| Forming speed | 0-18m/min |

| Producing speed | 0-12m/min |

| Main motor power | 15KW,Chinese famous brand |

| Transmission system | 1.0 double line chains |

| Control system | PLC Siemens brand |

| Dimension(L×W×H) | Approx.10000×1400×1600 mm |

| Weight | Approx.9500kg |