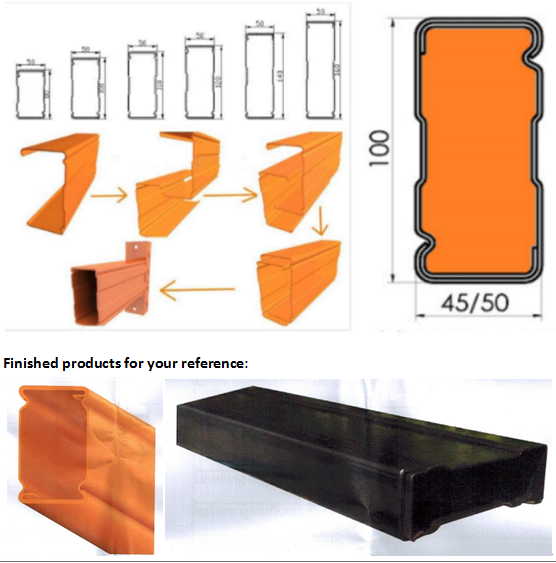

Box beam roll forming machine

Box beams are made from two identical channel sections nested together to form a box, Box beam is the most widely used beam, as the structure is the most strong compare with other type of beam.Box beam roll forming line is the essential for its production.

The drawing profile of box beam

First part: C shape roll forming machine

1: Coil width: according to the profiles

2: working speed:4-12m/min

3: roll station: 16 stations

4: material of roller: GCr12MoV steel,

5: material of main shaft: 45# steel

6: Main power: 15KW.

7: forming thickness:1-2.5mm

8: Transmission: chain

9: size of machine: about 10.5×1.5×1.2 m( L x W x H)

10: weight: about 16000Kgs

11: color of machine: blue and yellow

Second part: Box making roll forming machine by C channel

| Machine type | Interlocked C making machine |

| Working speed | 4 to 8 m/min |

| Material thickess | 1 to 2.5mm |

| Control method | Buck stop and control method |

| Rolling station | 8 horizontal rollers 4 vertical rollers |

| Roller material | Gcr15 after quencing steel Processing HCR at 58 to 62 degree. |

| Shaft material | 45# steel, after processing shaft diameter=80mm |

| Main power | 11 kw |

| Voltage | Customize |

| Machine color | Customize |

| Machine size | 5x1.2x1.0 meter |

| Delivery time | 45 working days |

Applications:

Used for the clap board assembly, U & box beam assembly, hydraulic flip over, electro slag welding, backing, SAW and end processing.

A video of the box beam roll forming machine

If you want to know more details about the machine, please feel free to contact with us.