Octagon pipe roll forming machine

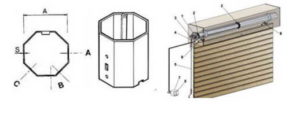

An octagon pipe roll forming machine is an equipment that manufactures the octagonal axes of roundel for rolling shutter doors that is assembled by steel slats or metal sheet panels.

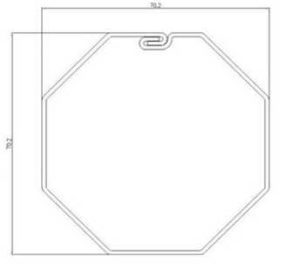

As its name shows, Octagonal tube is new type building material. Octagonal Tubes are widely used in petrochemical, power plant depressurization, aerospace, ships, machinery, communications, electronics and other fields. In the market, there are two types Octagonal Tubes, seamless and interlocked. The seamless Octagonal Tube is also made by cold draw pipe making machine. Here I will mainly show the interlock Octagonal Tube pipe with the interlocked seam. Here are tube pictures for your reference:

The raw materials for octagon pipe usually are galvanized steel or cold rolled steel of thicikness 0.4-0.8mm and the widths depend on the required octagonal pipes or tubes that is used as the axes of rolling shutter roundels.

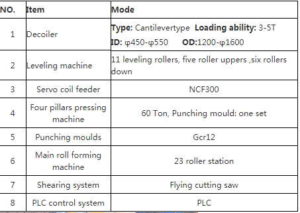

An octagon pipe roll forming machine usually consists of a manual decoiler, a pressing unit for holes, a roll forming unit, a cutting unit, control unit, and transmission unit. It can be running both automatically and manually under the PLC computer control system.