Strut channel is also called G-STRUT", "Kindorf", "Unistrut", "Superstrut", "UltraSTRUT", "Strut", "Metstrut", "Flexstrut", "JIKAstrut", "Nu-Strut", "Cantruss]", "C-Channel", "Canstrut, "Hilti Strut"), is a standardized formed structural system used in the construction and electrical industries for light structural support, often for supporting wiring, plumbing, or mechanical components such as air conditioning or ventilation systems.

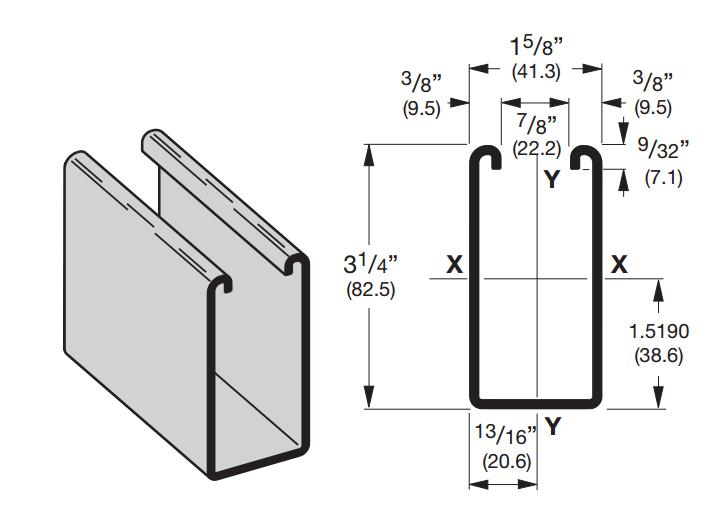

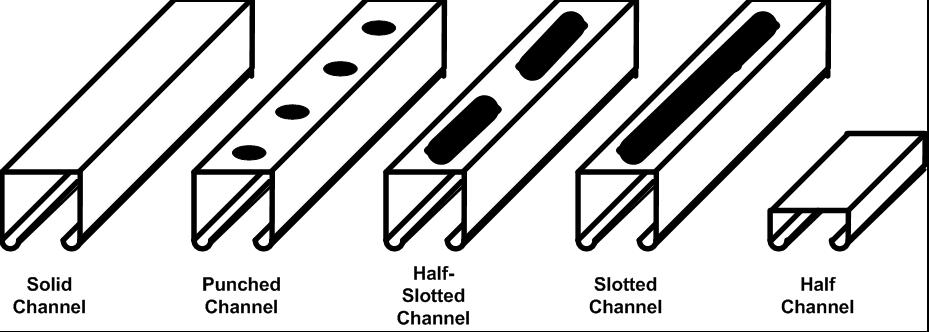

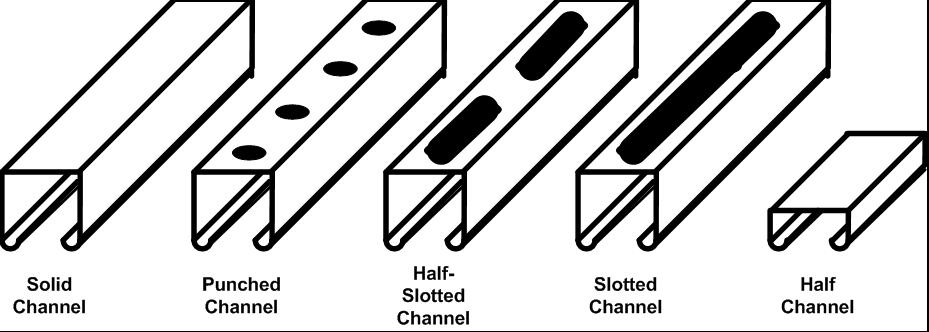

For making the introduction easily, here are some drawing profiles for your reference:

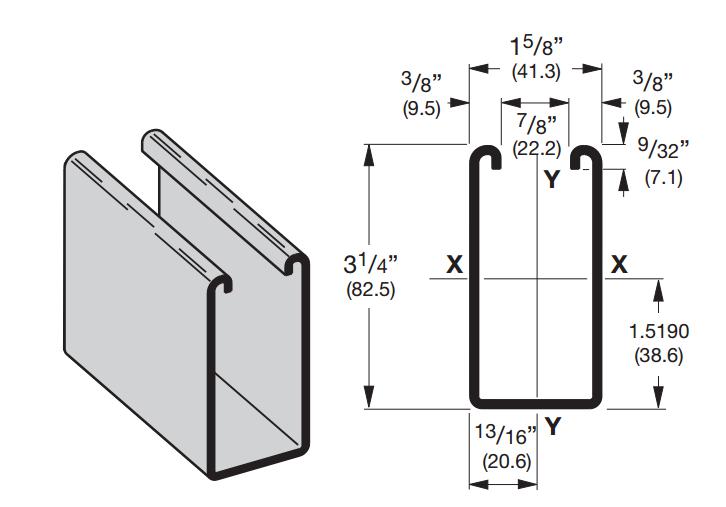

Here I will take a random drawing for example to show you how to design the machine:

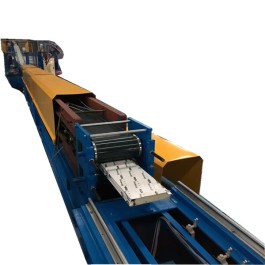

MACHINE COMPONENTS:

| 1 | Manual decoiler | 1 set |

| 2 | Leveling Machine | 1 set |

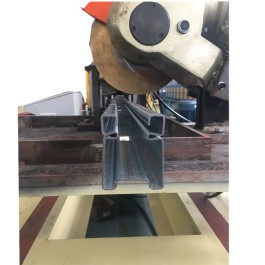

| 3 | Punching station | 1 set |

| 4 | Servo coil feeder | 1 set |

| 5 | Roll Forming | 1 set |

| 6 | Hydraulic Cutting | 1 set |

| 7 | PLC Control System | 1 set |

| 8 | Hydraulic Station | 1 set |

| 9 | Run-out Table-(Un-powered) | 1 set |

Main forming Strut channel with punching machine :

1) Forming steps: 18 steps

2) Outer diameter: 70mm

3) Machine frame (type): memorial arch frame, Thickness of memorial arch frame: 30mm

4) Roller information:

A. Raw material: GCr12MoV

B. Quenched degree: 56-58°C

5) Shaft material: 45# steel with heat treats and hard chrome plated on the surface

6) Main motor power: 18.5kw, Reducer ratio: 1:14,

Reducer Type: Hardened reducer

7) With cooling device

How to use of Strut channel:

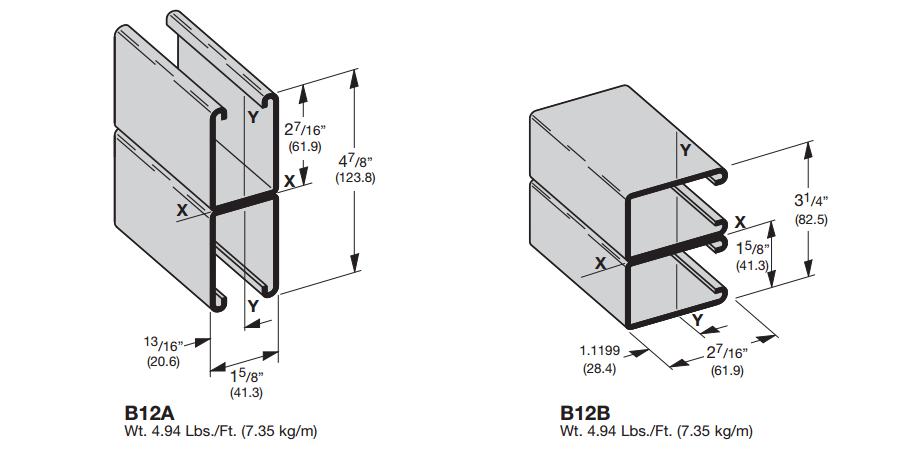

Channel & Combinations

Here are just two simple combinations, if you want to know more, pleasecontact me at any time.

Next: Storage shelf beam roll forming machine