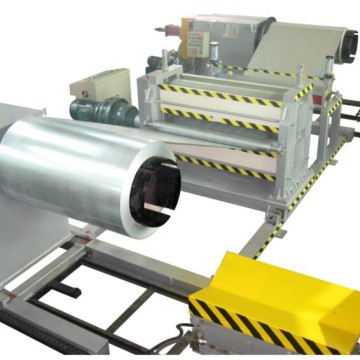

Steel plate embossing machine is the tool, which could be used for stamping logo, tag, patterns or others on the metal for some special functions like anti-slip on the floor decking, keeping warm for the vehicles. Different with the small embossing machine in the market, ours could help you embossing large scale metal plate from coil and then to recoil, the width of the steel plate could reach 1.5 meters or more. The working principle of the metal embossing machine is that through two rollers which have been curved patterns you need give pressure on the metal and then make the pattern on the steel plate.

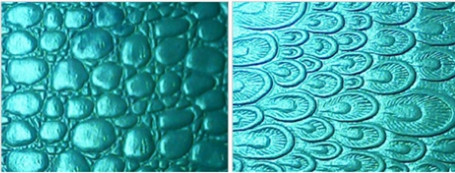

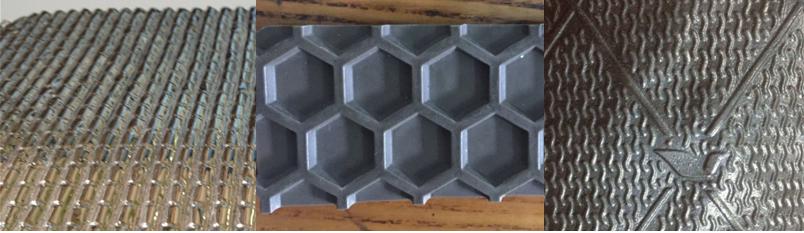

Here are some samples for your reference:

All above samples could be made from steel common plate to recoiled steel plate with flower type.

The following information is about the metal plate embossing machine:

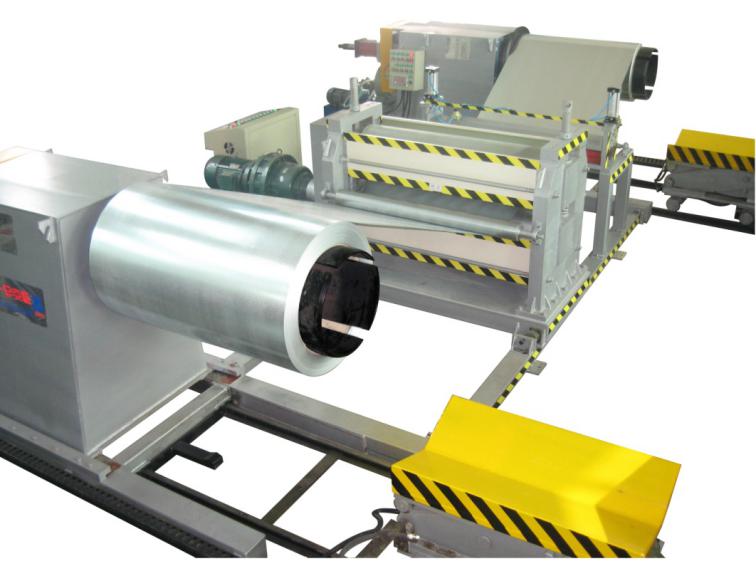

Whole Line of Peal Embossing Rolling Machine

First Part: Brief parameters of the embossing machine

1.machine size:3300×1200×1500mm;

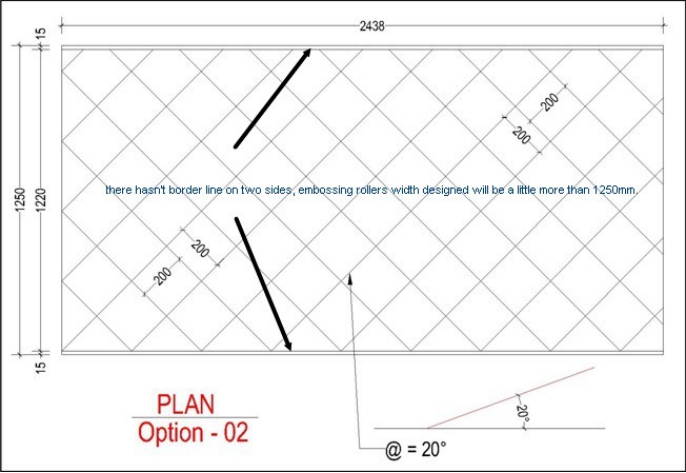

2.Embossing roller size:Φ320×1400mm;

3.Embossing type:Pearl samples;

4.Roller material:42CrMo alloy steel

5.Hardness of rollers:Surface to be case hardened 55 to 58 Rc, Top Roll/Bottom

Roll: Driven by adjustable herringbone gear set

6.Embossing mode:Up and down concave and convex roller to press;

7.Pressure regulation:Screw pressure;

8. Supported material: 0.5mm×1200mm Aluminum coil

9. Motor power: 480Volt, 60Hz, 3 phases

Brand: Siemens

10. Reducer: China World Trade Center speed reducer

11. Bearing: domestic brands in Wafangdian City

12. Working Speed:0-18m/min

13. Delivery Time: 50-60 working days

Operator

Operator controls labelled in English

Manuals: Operator and maintenance manuals in English

Second part: Decoiler & Recoiler

The parameters of the Decoiler:

1. Machine size:3900×1200×1800mm;

2. Inner diameter:Φ500-510×1350mm;

3. Max loading weight:2500Kg to 5000kg;

4. Cylinder size expansion: hydraulic cylinder control;

5. Roll brake: magnetic particle brake control;

Ⅱ、Recoiler parameters :

1、Machine size:4100×1200×1800mm

2、Style:Φ500-510×1350mm;

3、Loading weight: 2500Kg to 5000kg;

4、Cylinder size expansion: Hydraulic cylinder control

5、Motor:15Kw Frequency conversion motor SIMENS

linear speed 0-20m/min;

6. Roll Loading: Hydraulic Cylinders

Third part: Shearing system

1.Type of cutting power: Hydraulic

Cutting balde material: Gcr12, quencing at 58 to 62 degree to make sure hardness and long time to use

Cutting tolerance:±1mm

Cutter blade more pair we will give one more as spare part

Cutter quantity: 1

Working pressure: 20 MPA

Note: we add this before the recoiler, for after embossing, the coil change to thick and the diameter will be quiet big. For example, maybe the coil just 100 meter, the outside diameter will be quite big. So this is nessary.

2. Hydraulic system

Hydraulic oil 46#

Hydraulic power 4kw

Cutting length As required

Brand Japan Youyan series

No distorting or wasting. High level safety factor.

Fourth Part: Control Device control By PLC

PLC language English and or others (or as required)

Touch screen: 4.7Inch

Function: Automatic length and quantity measurement

Brand: Mitsubishi

For this machine if you need to know more information, please contact us as soon as possible.

Next: Steel Fence Pillar Rolling forming machine for Canada