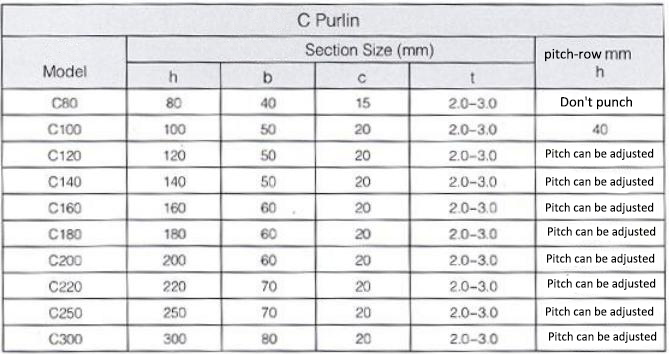

The 80-300 Broken C Purlines roll forming machine can produce C purlin in various specifications by adjusting spacer to change sizes. Production process uses automatic PLC control mode, easy to handle, vertical pitch, quantity and other parameters, cutting, molding. The machine could make C shape purline from size 800 to 300mm and the material thickness is from 1 to 3.5mm. Here is the table of C shape sizes for your reference:

Here is Broken C Purlines roll forming machine pictures:

Broken C Purlines roll forming machine parameters for your reference:

Advantage: Automatic length cutting, automatic punching, high degree of automation, quick and easy installation

C-beam machine is a set of rollers to produce a variety of specifications C purlin roll forming machine finished single

It consists of passive loading rack, leveling device, punching device, after forming cutting device, hydraulic station, and computer control systems. This machine adopts automatic flying saw punching, easy to operate features.

Voltage: 380V 50HZ 3Phase or customize

Frame: 400 H steel

Drive mode: differential gear

Main axle material: GR15

Material of shafts: 45# steel

Diameter of shafts: φ80mm

Number of rollers: 12 rollers

Main power: 11kw(cycloidal planetary gear speed reducer)

Forming speed: 8m-10m/min

Adjustment method: Half seams type Looper

Features of Broken C Purlines roll forming machine:

1.Support sizes range from 80 to 300mm.

2.Ajust sizes method by adjusting spacer, easy to make.

3.Before shearing, so you do not need to worry shearing problem.

4.If you like post shearing, we will give shearing balde as free.

5.Fully automtic PLC control systme to control punching holes position and distance.

6.Strong chain transmission to make sure working steady.

7.This machine frame and shaft to make sure machine long time working.

For Z purline machine webpage, please refere to next article. And if you like fully automtic C &Z pulrine machine, please contact us at any time.

Next: Crash barrier roll forming machine