Zhongtuo Roll Forming Machinery Co., Ltd. From 1996, is specialized in manufacturing of cold roll forming machines, like roof tile and wall panel forming machine, floor deck forming machine, light keel machine, C and Z purlin machine, tube mill and so on.

Metal Stud Wall Framing machine is designed mainly for making C stud and U track in batch and fully automatic. In modern society, the C channel and U track are mainly used for false ceiling making and drywall making. For this type machine, we have high-speed machine to 50m/min and normal speed machine of 25m/min. Meanwhile one machine for many type and sizes are possible.

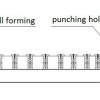

This is the Process drawing of our Metal Stud Wall Framing machine:

The main parts of our Artistic Popular Metal Stud Wall Framing machine

1.Decoiler

Usage: It is used to support the steel coil and uncoil it in a turntable way.

Passive uncoil pulled by roll forming system.

2.Feeding and leveling

This part will level coil to make sure it is neat clean and straight.

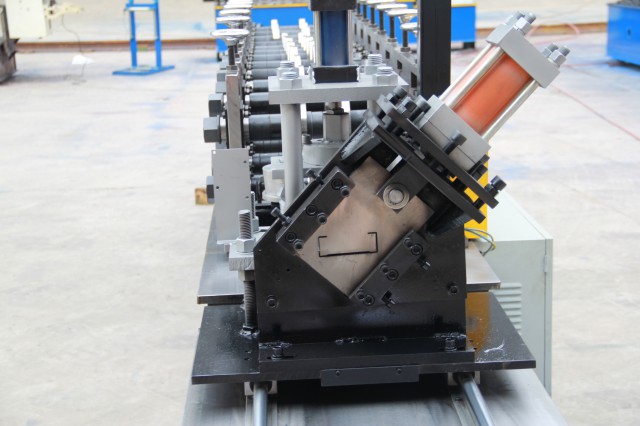

3.Roll forming machine

our one machine can product different types material , just through adjusting the width of the rollers and changing the special rollers.

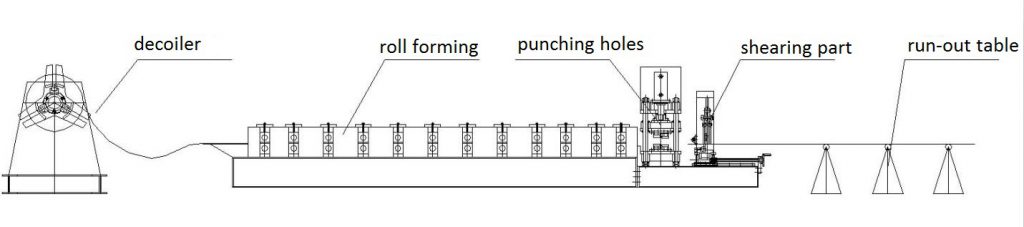

4.Punching part

This part will together with shearing part.

5.Shearing machine

6. Hydraulic Station

Components: The system includes a set of hydraulic tank, a set of hydraulic oil pump, and four hydraulic pipes. And two electromagnetism valves: one is for punching hole, one for cutting.

7. Electric Control System

Feature:

1.Adopted PLC, transducer, touch panel from Delta Taiwan to ensure high speed with stability, precision and lifetime.

2.Other electric element are Delta

3. Equipped with movable switch, air break, radiator, transformer & electric leakage protector for operation convenience and safety.

8. Run-out table

It adopts welded steel and supported roller to transmit the products.

Last week, we have already made an order with the customer who comes from Iran.