Product Details

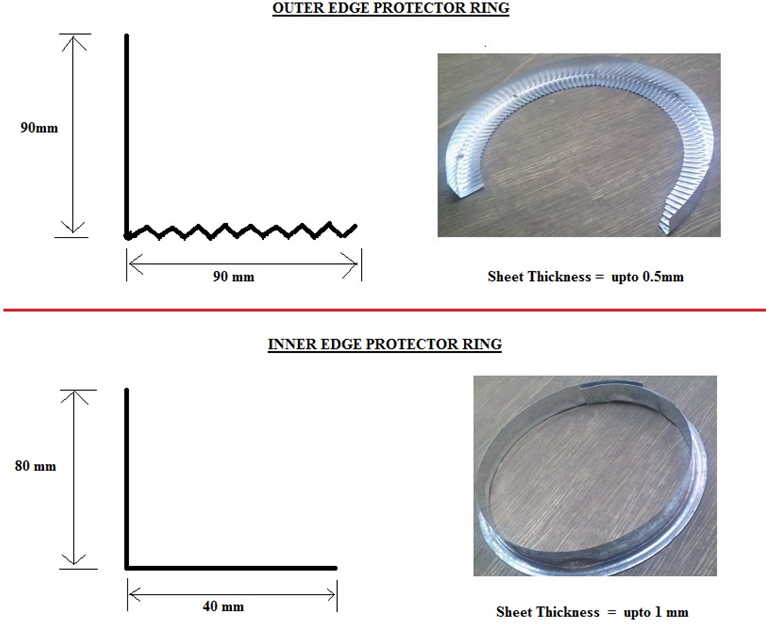

Steel coil inner or outside edge protector rolling forming machine can help you make the steel edge protecter inner and outside in batch both fully automatic. One machine with two gear embossing machines and then it can be used to make those two inner and outside coil edge protectors. Here are two drawing profiles for your reference:

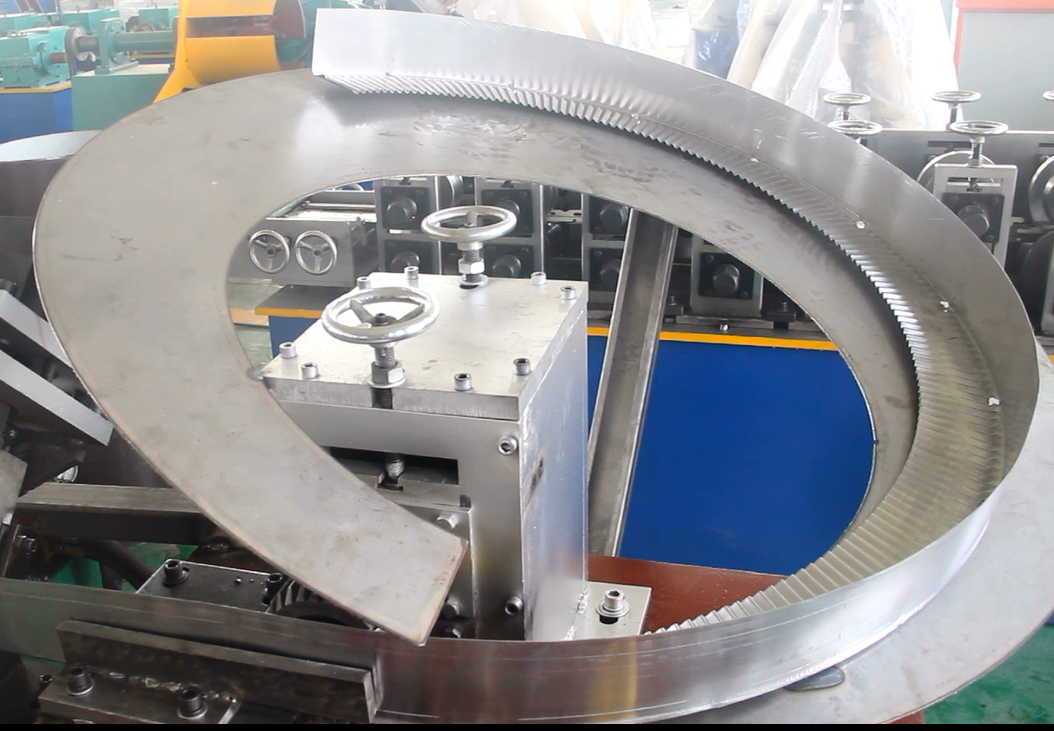

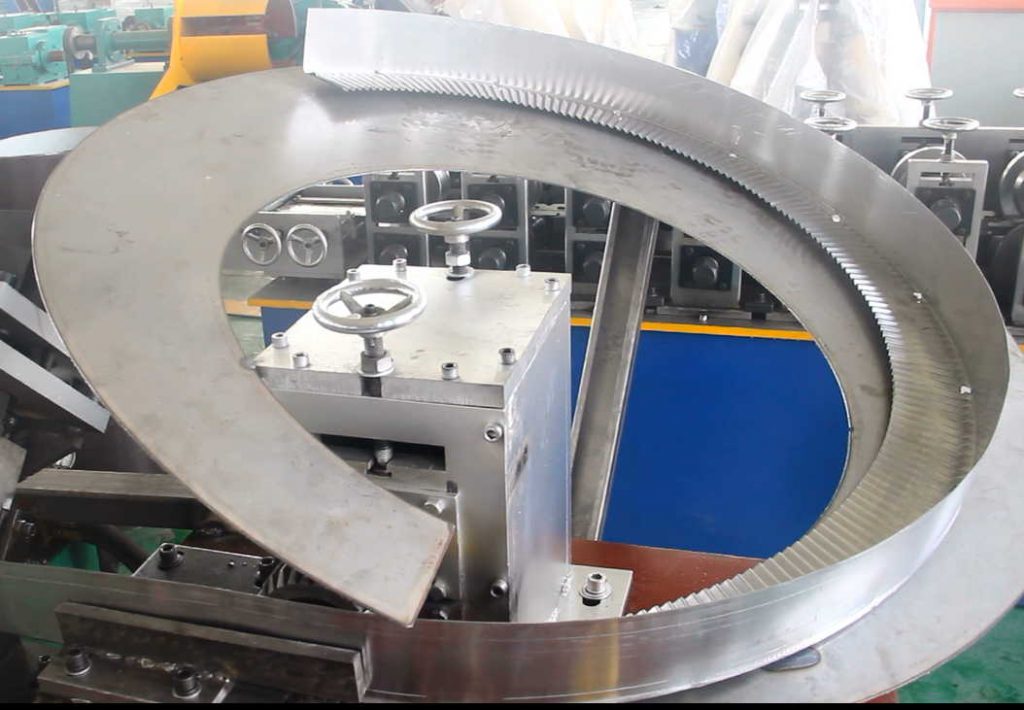

Finished products for your reference:

The machine is composed by the following elements:

Manual decoiler, leveling machine, punches machine, servo coil feeder, rolling forming machine, round circle making machine and PLC control system, hydraulic system.

For this machine, if you have any problem, please contact us at any time.

Prev:

Instruction of install machines for customers in United Arab Emirates

Next: Italy design rolling shutter guardrail rolling forming machine

Next: Italy design rolling shutter guardrail rolling forming machine