Double metal corner is made of high quality galvanized material, it is good for anti-aging, anti-corrosion and anti-fire, effectively prevent rusting. Meanwhile metal corner a precise acute angle size design, to avoid the corner by the impact of stress concentration, the external is uniformly distributed around the edge of the part, the effective protection of the positive angle intact.

The metal bead is divided into punching and expansion, not only convenient nail and the bead and the corner parts of the gypsum board or other adhesive materials with more solid. Metal corner construction installed without wooden boards, may be the primary plasterer also make perfect corner straight, shorten the construction time, and effectively reduces the construction cost.

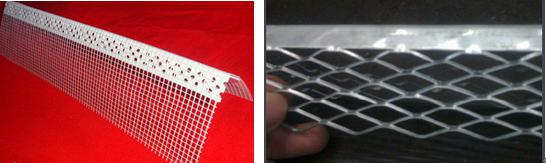

Here are two pictures for your reference:

The Metal bead with punched lip production line is composed by the following elements:

| NO. | Item Name | Quantity |

| 1 | Decoiler | 1 SET |

| 2 | Punching machine | 1 SET |

| 3 | Coil feeder | 1 SET |

| 4 | Main roll forming machine | 1 SET |

| 5 | PLC control system | 1 SET |

| 6 | Runout table | 1 SET |

Here are some main machine parameters for your refernce:

Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, gear transmission (the first and the last roller, the down roller should be attached with the upper one with the gear drive.), roller surfaces polishing, hard plating, heat treatment and galvanizational treatment. The polished surface and the heat treatment towards the molds also can keep the molding plate surface smooth and not easy to be marked when it is being stamped.

Length of the main part: about 3000х800х1400

Weight of main part: 3 tons

Voltage: 380V/50HZ3Phase (as customer's request)

Roller fixer: Guide column

Frame: middle plate welded

Memorial arch frame type

Frame thickness: 30mm

Drive mode: gear

Material of rollers: GCr12MoV

Material of shafts: 45# steel with tempering

Diameter of shafts: φ60mm

Number of rollers: 10 rollers

The different sizes can be produced on this machine by adjusting the feeding width.

The working principle of the machine is that:

Decoiler-- punching machine to punch net-- coil feeder to feed coil to main roll forming machine-- Main machine to do the roll forming --shearing system runout table

Here is the machine working video for your reference:

For this machine, if you want to know more questions, please contact us at any time.